W wielu branżach w wyniku epidemii Covid-19 nastapiły zmiany. W tym artykule koncentrujemy się na zmianach jakie zaszły oraz rosnących inwestycjach w automatyzację w branży opakowaniowej.

While many industries are losing business and suffering severely from the COVID-19 pandemic, large parts of the packaging sector seem to be experiencing quite the opposite. Adequate packaging is now needed more than ever. Have a look at these significant trends and how to make the most of them.

Growth in difficult times

Already since the start of the pandemic, we have witnessed a much higher demand for packaging in food industries as consumer demands have risen, particularly for shelf-ready packaging in the retail industry. This change is recent – but it’s nothing new. Looking back at the years following the last global financial crisis of 2008, the packaging industry actually saw an increase in investment compared to other industries and a vast growth in certain sectors. Now the story is repeating itself, and this time it’s amplified by the strong demand for hygienic solutions.

Sustainability slowing down

Environmentally friendly packaging solutions have been a constant in packaging trends over the past decade. While COVID-19 is not likely to impact consumers’ behavior on shopping ecologically, the speed of growth of this sector might be affected by the crisis. One reason is that the gastronomy and food catering industry might have to turn to disposable containers in order to minimize the risk of virus transmission. While this trend is not likely to continue after the end of the health crisis, it does indicate a new and higher packaging demand in the short-term. Because health and safety concerns about hygiene will probably be prioritized over environmental sustainability as people continue to tackle the pandemic.

Rocketing e-commerce

With most shops and physical retail spaces on lockdown the world over, online delivery services have never been more in demand. Since packaging is a very important prerequisite for all e-commerce trade of physical goods, there is a new value placed on packaging that guarantees defensive protection and prevents damage to the goods, while being financially effective as well as “return-ready” to improve the retailers’ chance of getting a product back into their stock as efficiently as possible. Disposable packaging is also in higher demand as consumers opt for more takeaway food delivery. With many businesses investing in e-commerce as a primary revenue stream, and with so many consumers discovering the convenience of this mode of shopping, it is likely that this behavioral change will last beyond lockdowns.

Automation – the safe and productive solution

Over the past months, many office workers in Europe have endured a “work-from-home” policy. Meanwhile, the majority of factory workers have had to implement social distancing measures in order to stay safe while keeping up productivity. This has proven to be one of the greatest challenges presented by the COVID-19 crisis so far, and there is still a great need for improvements.

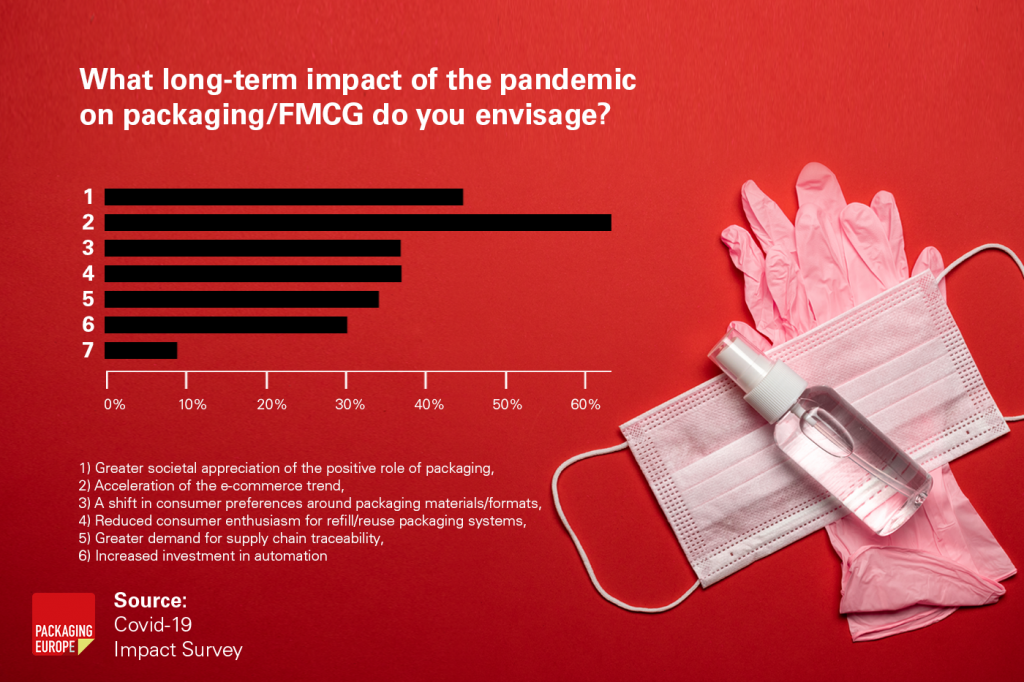

One way to ensure safety and productivity at packaging plants is to increase the use of automated solutions. In a survey recently conducted by Packaging Europe, 20%* of the packaging professionals answered that they are shifting to rely more on automated and machine-operated processes. Around the same proportion of respondents also believe that increased investment in automation is on its way to becoming the new normal.

We’re here to help you

FlexLink has solid experience in creating easy-to-use and cost-efficient robotic solutions for the packaging industry, and we can help you automate three labor-intensive production processes:

• Depalletizing at the beginning of a line

• Material feeding and conveyor systems in the middle of a line

• Case packing and palletizing at the end of a line

Contact us and we’ll help you develop your operations so that you can maintain a safe social distance while making the most of these challenging times.

Dodaj komentarz