Noise exists more or less in every manufacturing industry and is hard to get rid of completely. However, it should be reduced to a minimum since a working place with a lot of noise, or unwanted sound can affect both the employees and the business in a negative way. In this article, I will describe how noise arises in the manufacturing industry, how it can be prevented as well as why it is important to reduce the noise to a minimum.

Colliding products create noise in the manufacturing industry

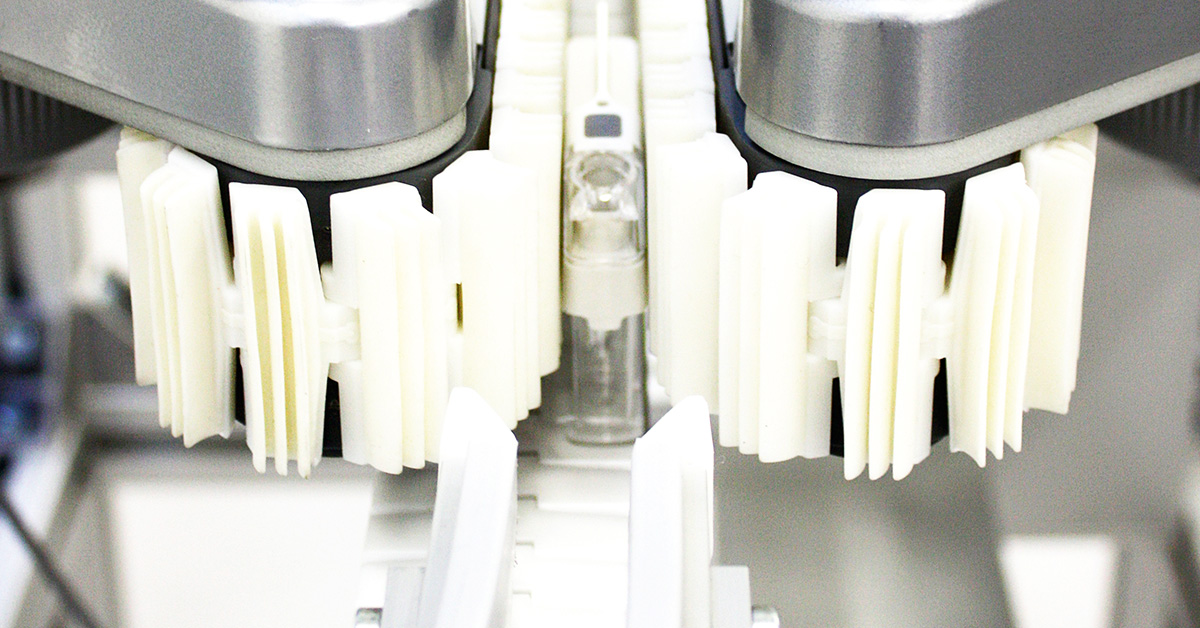

Noise in manufacturing industries originates primarily from the products being produced. Therefore, the noise levels differ depending on industry and what type of material the products are made of. For example, the noise level is often higher in the automotive industry than in the pharmaceutical industry. Noise can also arise when products, such as glass bottles, come in contact with each other on the conveyor belts.

Sound absorbing material decreases noise from conveyors

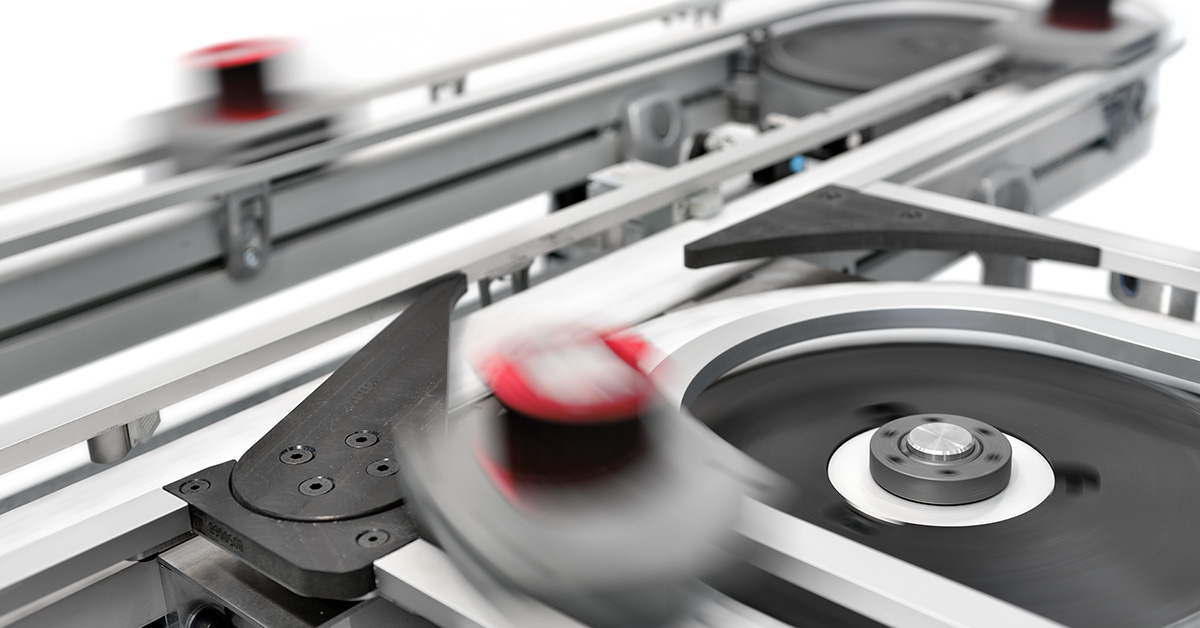

Machines and conveyors can also cause a certain noise level, where factors such as speed and material choice play a big role. For example, high-speed conveyors normally generate more noise than conveyors that run slowly. The design of the machine components has a strong impact on the noise. For example, the geometry of what may look like an insignificant component can play a major role in the generation of noise. Also, the design affects how good the components fit together and how they are assembled. If, for example, two connected surfaces are not perfectly aligned they can create a very high noise when for example a conveyor chain or belt runs over them. Also, different types of materials can make a certain difference in the noise, where for example a softer plastic absorbs noise better than steel.

Low sound levels increase safety at the workplace

When it comes to noise, we tend to talk about three different ways a person could be affected. The psychological impact often results in irritation and stress, which lead to reduced working capacity and performance. Continuous exposure to noise can lead to physical consequences such as damages to the inner ear, increased blood pressure and irregular breathing. In addition, noise can be an isolating factor that stops the ear from perceiving other sounds such as warning signals. Thus, a high noise level can increase the risk of accidents at the workplace.

According to the European Machinery Directive, the accepted noise level is below 85 dB(A). When exceeding 85 dB(A), measurements must be taken to reduce the exposure, beginning with a reduction at the source.

Prolong your equipment’s lifespan by avoiding friction and wear

Noise is often equal to friction and increased wear on the equipment, which has a negative impact on the equipment’s life span. By using modern machine technology, smart control systems to avoid products colliding with each other and proper design of the equipment, the noise level can be reduced to a minimum.

Customized production flow solutions minimize the noise in the manufacturing industry

Maintaining low sound levels is a big part of the concept of creating an effective and smart production where both humans and machines work at their full potential. We, at FlexLink, work hard to design our products with the right geometries and use sound absorbing materials to reduce noise. We design our material flow solutions in a way that keeps the products from colliding with each other.

We also use smart line control, adopting the conveyor speed to the varying states that exist in all manufacturing lines and in addition, “Time out system” that automatically starts and stops the system. This means, if for some reason the production is down, the system automatically stops. These concepts not only reduce the sound level, but they also reduce wear on the products and the equipment as well as reduce energy consumption.

Creating a pleasant industrial working environment as well as designing high performing production flow solutions is our core business. Therefore, minimizing noise is a big part of our offer and promise to our customers.

Are you more interested in safety measures to create a good working environment in the manufacturing industry? Read our blog articles “CE mark your machine by using the Machinery Directive” and “Safety engineering reduces risks and threats in production“. Please contact me if you have any questions and visit our website for more information about FlexLink as well as our products and services

Leave a Reply