Linear Motion Technology is an innovative transport solution that allows high precision and positioning in product handling, process reliability, and efficiency. A magnet-equipped pallet enables rotating movements, particularly useful for processes requiring high accuracy, high-speed repeatability, and flexibility. The integration of linear motion technology with a conveyor system has many benefits. Understanding the options will help determine your production line’s ideal linear motion integration (patent pending), also called LMI.

The pallets of integrated linear motion technology look almost identical to standard pallets. However, the advantages of the technology are worth taking a closer look at. Linear motion technology is becoming increasingly popular in many industries and now has an absolute raison d’être in modern production lines. The motor-driven pallet, equipped with a magnet, enables the pallet to run in both directions and allows multiple stop positions. The technology is often applied in the automotive industry, for example, in production line transport, product handling, and positioning. In addition, the technology is widely used in pharmaceutical automation, life science, and the FMCG industry. The technology has many other application areas and is especially useful when processes need to be flexible and efficient. Let’s have a closer look at all the benefits.

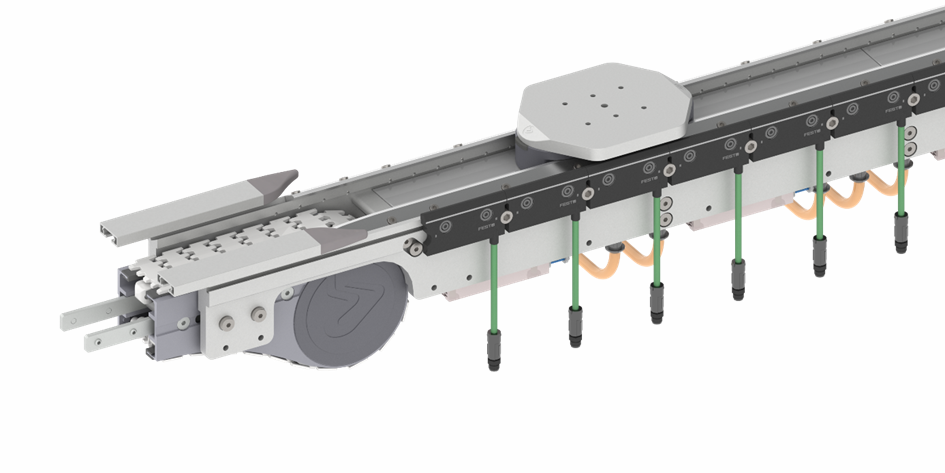

How Linear Motion Integration works

Components of the linear motion system are a motor, which powers the system, a thrust mechanism, and a guidance infrastructure, such as a rail. Magnets are placed in the front of the pallet to achieve a smooth transition without advanced bridges. As a result, there is no need for an extra stop before the linear motor or running the in-feed conveyor at high speed. Thus, the speed and acceleration obtained are faster than standard conveyors for pallets. The pallets are designed to work with integrated linear motion technology and with traditional conveyor functions. With linear motion, it is possible to enable back-and-forth movements. This allows the pallet to move in both directions with multiple stop positions. Therefore, it is easy to control each pallet individually with precision.

Combine Linear Motion Integration with standard conveyors

The FlexLink X85P conveyor can currently be combined with MML from Rockwell or MCS system from Festo and Siemens. The main benefit of integrating linear motion technology with standard conveyors is to allow a quick and easy implementation in both existing and new systems. To combine the technologies efficiently, you must achieve a smooth transition between linear guides and standard conveyors. Otherwise, the pallet would need to stop shortly before reaching linear motion, which leads to decreased speed and production efficiency. With LMI, you can control each pallet individually with precision and run them in both directions. This leads to increased flexibility to allow different pitches and stop positions. Picking products from a continuous high-speed flow and sending batches to other locations is only one example of its uses.

So, with this new technology comes many new possibilities that would have been challenging to solve with traditional technology in the past, such as positioning several pallets to unload multiple products simultaneously. This helps improve efficiency in a line or eliminate waste due to product change setup. So, using a combination of linear motion technology and standard conveyors allows increased productivity while saving valuable floor space and staying cost-effective.

Linear motion technology can be used across all industries, such as Automotive and FMCG

Many other industries, such as medical, packaging, aerospace, and food, use Linear Motion Technology. It can be useful in any production facility with a production flow that needs several processing steps in a straight line. The benefits of the application increase when connected to other technologies, such as plastic chain conveyors. Continuous high-speed flow that accurately sends batches to different locations is only one example of its many uses.

When to use linear motion technology

The integration of linear motion brings the most advantages when there is a need to improve production efficiency while minimizing future potential costs. Combining linear motion technology with standard pallet conveyors gives flexibility in process sequences and reduces retooling time, thus increasing productivity. Combinations can be used in single or several sections of linear motion with pallet conveyors.

Furthermore, the pallet conveyor and the integrated LMI are seamless both infeed and outfeed. So, linear motion is the right solution for you when you need to run your conveyor at high speeds with maximum acceleration, synchronizing its motion with external equipment, or running the load more smoothly.

Advanced solutions that give production efficiency

By combining linear motion technology with traditional conveyor technology, it is possible to:

- Control each pallet individually with precision.

- Run the pallet in both directions and allow multiple stop positions.

- Synchronize pallet movements with external machines

- Use pallets in high-speed applications with fast acceleration and deceleration

Increased productivity and less downtime

Choosing the right solution for your product flow needs is critical when planning a production line. Increased productivity, improved efficiency, and minimal line downtime are just some of the topics that determine the success of a production line. To find out more about our linear motion technology solutions, or if you need help developing your automated production flow solutions, feel free to contact us with any questions.

Contact us to learn more about how to increase production efficiency. Also, feel free to visit our website and follow us on LinkedIn for more regular updates on industrial automation and robotics.

Leave a Reply