In 2020 we celebrate four decades of successful business. What started out as an idea to improve factory working conditions has turned into this global enterprise that today enables companies all over the world to process goods safer, smarter and at a lower operating cost. Now it’s time to celebrate our pioneering idea and our position as the world leading provider of material flow solutions.

How it all started

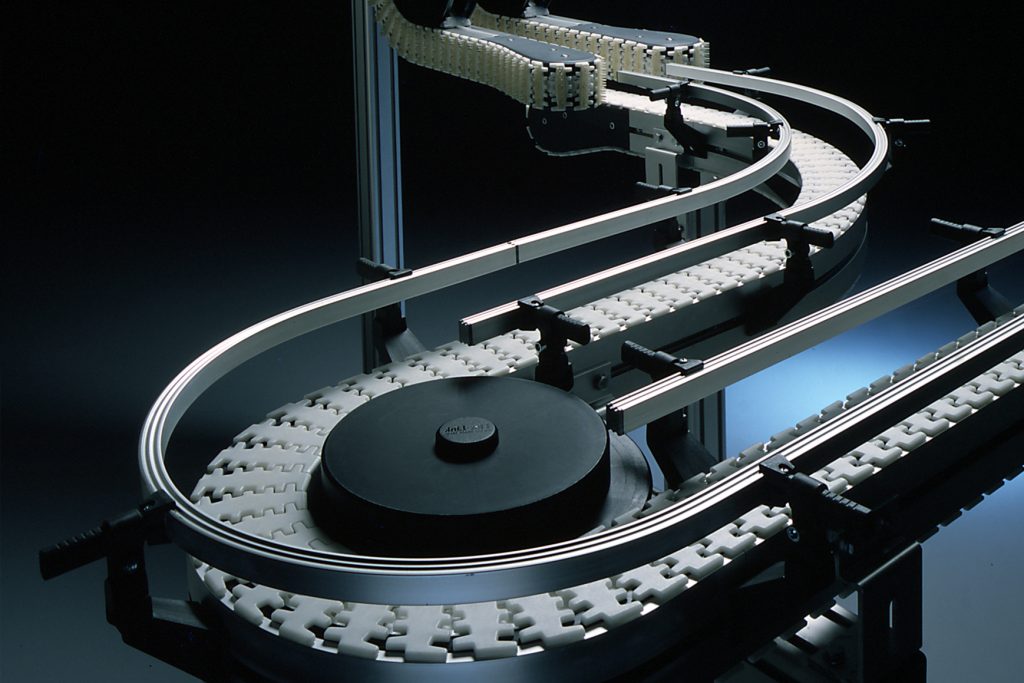

Forty years ago, a team of inventive developers at the SKF ball bearing factory came up with an idea which was as brilliant as it was simple: instead of having people moving components from one production stage to another, that heavy and repetitive work could be handled by an automated transport system. And if the system was made modular, these new transporting lines could be made flexible too. This pioneering idea lay the foundation for our modular conveyor platforms and since then, our automated material flow solutions have transformed modern industrial production.

The first conveyor range, called XL, was designed to transport light goods such as bearings and packaged food. The solution featured the world’s first joint chain to move vertically as well as horizontally, and the three-dimensional conveying became a huge success. Soon the manufacturing industry wanted more, and during the 80’s and 90’s we launched a range of new conveyor platforms to satisfy the various customer needs:

- XS: designed for small goods such as syringes, vials and electrical bearings.

- XM: suitable for medium size goods such as plastic bottles, creams and jars.

- XH: specialized for large items where the point of balance is off-center.

- XK: heavy-duty platform for the automotive industry.

Product innovation

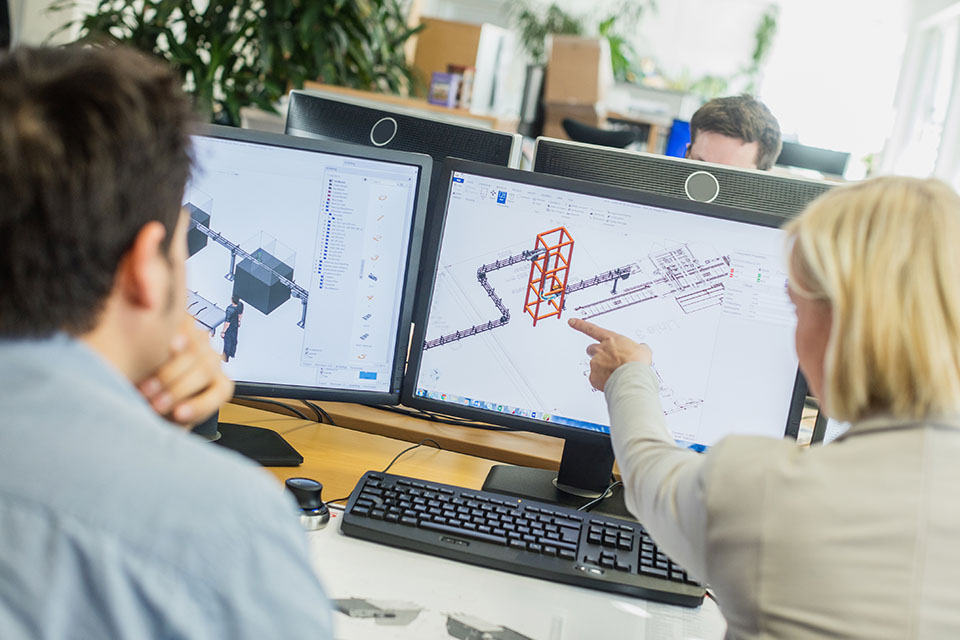

Motivated by the success of our conveyor systems, we continued to develop customer-centric products and services. We launched the Dynamic Flow ConceptTM to optimize line balancing; the FlexLink Design Tool, enabling customers to design their own lines and simulate production flows; and the hygienic WLX wide belt conveyor. Many other innovations were introduced, helping manufacturers to make their operations more efficient and profitable.

In 2012 FlexLink became part of the Coesia group, and has since focused even more on innovation and user experience. Since then, we’ve taken process automation to a new level by launching the collaborative robot palletizer RC10 and the industrial palletizer RI20, and more is soon to come.

Today and in the future

Today, FlexLink stands as a global, reliable partner for leading manufacturers in Fast Moving Consumer Goods, Food, Automotive, Batteries, Pharmaceutical, Tissue & Hygiene and Tobacco. Over the decades, we have opened distribution centers and manufacturing sites across Europe, North America and Asia and as we speak, we’re represented in more than 60 countries and operate directly in 26 of them.

“FlexLink is always striving to help brand owners increase efficiency and reliability,” says Paolo Pusceddu, Chief Sales Officer. “We will continue developing products and solutions that provide our customers with the best answers to their production challenges.”

Learn more about our history and today’s offer of efficient material flow solutions.

Leave a Reply