Anticyclical by tradition, the pharmaceutical industry is one of the sectors that best cope with the difficulties caused by the pandemic. It keeps up with new responsibilities that are generated by the need to increase efficiency and speed in producing new pharmaceuticals and placing them on the market. The crisis that COVID-19 has caused, in particular, highlights the importance of delivering results fast, increasing efficiency and eliminating errors in – but not limited to – the vaccine manufacturing process.

A growing market that has never seen a crisis

The size of the global pharmaceutical market is valued around 1.25 trillion USD and is expected to grow at a compound annual growth rate (CAGR) of 13.74% between 2020 and 2027 (Source: Grandview Research). The United States has the largest pharmaceutical market in the world, generating about $484.8 billion USD (Source: Pharma Approach). However, also other countries such as Japan and China are experiencing a fast growth, the latter forecasted to surge up to almost 574 billion U.S. dollars by 2022 (Source: Statista). Pharmaceutical supply chains proved to be resilient to the shock of COVID-19. Therefore, the subsequent economic crisis is not expected to hurt the industry in the short or long term. Pharma’s response to the pandemic – as far as the development and distribution of vaccines are concerned – has made it to the headlines. However, many of the challenges facing the industry are not exclusively related to corona virus.

Pharma 4.0 – the digital transformation

The impact of the digital transformation in the pharmaceutical industry is wide and deep. Many results are being currently obtained and many opportunities will be opening in the near future, also due to the pandemic. The pharmaceutical companies that lead the future of the industry are alert and able to detect. The trends that are beginning to take shape on the horizon. This is because the pharmaceutical industry presents specific sensitive issues concerning safety, regulations and efficiency in production and delivery. According to forecasts, the development of AI systems, tightly connected to predictive software, is on top of the list. Another big topic is the capacity to analyze big data. Effective execution and management of digital processes can be challenging, but failure to adopt digitalization’ may cause bigger risks.

Developing efficiency to improve time to market

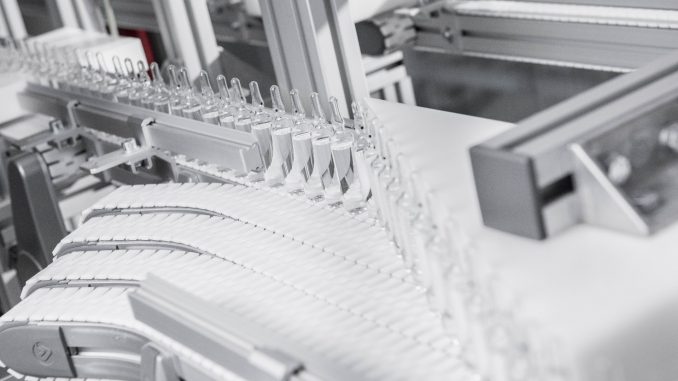

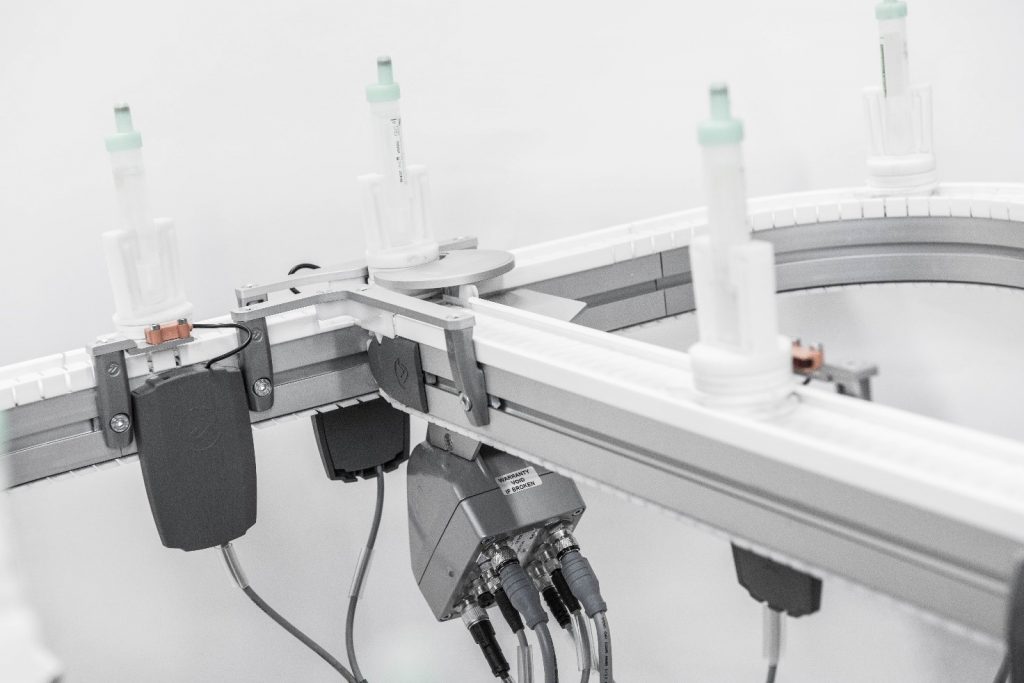

The number of clinical trials has grown significantly in the last years. Between 2000 and February 2021 366,000 clinical case studies were completed worldwide (Source: Data Trial). The figure grows at the same pace as the investments in research and development. The investments reached 186 billion USD in 2019, the last year for which data are available (Source: Statista). Pharmaceutical companies strongly support research, but one of the most critical areas concerns production efficiency. It is essential to begin with an effective design of the production line to speed up time to market. This results in a need to be customized with turnkey solutions able to ensure flow efficiency and continuity, together with a continuous control system. Balancing the flow with buffer solutions is a key aspect. Furthermore, the prevention of unnecessary stops or errors is of high importance, for example due to label refill, etc. It is easy to improve the process with some simple changes, which can be easily integrated in the production line design.

Production control and monitoring

Production control and monitoring are fundamental to ensure that pharmaceuticals are adequate, safe and reliable. Therefore, it is standard to continuously monitor the production processes through objective measurements during all production stages. This allows pharmaceutical companies to obtain real-time critical data on the quality and performance of machines, materials and medications themselves. The overall goal is to ensure the highest quality of the product that is placed on the market. For this reason, it is important that the processes of control and monitoring take place continuously and in different phases. Also, by means of automated systems, to achieve a level of consistency, economy, and safety that could not be reached by manual operations. Predictive software and simulations can further contribute to find the right solution to minimize hidden costs. Another benefit is to detect errors in advance, before high investments are made.

The future of the pharma market: simple solutions for complex problems

Due to its special procurement, the pharmaceutical industry has developed technologies that are now being applied in other industries. One example is serialization. Pharma serialization is the process of assigning a unique code to the packaging of each drug and printing that code on the packaging in some way. There are two main points in this definition. The first is the unique code and the second is the packaging of the drug. This technology can also be helpful to other industries, such as food production. Even more benefits can be gained there, including for the consumer.

New challenges emerging through COVID-19

In the future its processes are going to become even more technologically-oriented. On the other hand, the experience of COVID-19 has taught us that it is necessary to simplify the access to treatment and the use of medications by a larger part of the population. Medications themselves need to become more user-friendly for patients, who should be able to understand dosage, use and effects. Serialization is the keyword to fulfill this requirement. Furthermore, the supply chain will have to implement processes that lead to increasingly ‘smarter’ medications and improve the efficiency of with which products are developed, packaged and placed on the market. Improving production capacity therefore plays an essential role in the process, as it plays a crucial part in allowing fast access to treatment with necessary medications.

You are always welcome to contact us or visit our website. To never miss out on any of our blog posts, follow us on LinkedIn. We will continue to share our knowledge in industrial automation and production efficiency with you.

Leave a Reply