The manufacturing industry is going through major changes due to the digital transformation. Therefore, in order to remain future-proof and competitive, manufacturing companies today must face complex and innovative changes in their productions. Preliminary technical studies, also called pre-studies, help you analyze your production, identify potential improvements and define how new technical innovations can help improve your production results.

Why conducting a technical pre-study?

The intention of a technical pre-study in the manufacturing industry is to analyze a production in order to define alternative technical solutions that can help improve production efficiency. Pre-studies are usually conducted by an external actor that can examine the production in an objective way. The studies can also be done in order to create a complex technical solution for a specific task, generally increase production efficiency or help productions that strive to achieve smart factory automation. They are relevant in all types of manufacturing industries and address companies that want to grow, reach higher overall equipment efficiency (OEE) and a faster return of investment (ROI).

Invest in the right technologies at the right time

Many different competencies are required in order to achieve a successful pre-study and define how to invest in the right technologies at the right time. Areas that need to be analyzed are, for example, production automation, material flow logistics, data processing, control and instrumentation as well as different lean processes. The studies also need to be executed with innovation, standardization, and sustainability in mind.

A simulation model allows for risk-free collaborative tests

The first step in a pre-study is to identify the production needs to understand the factory operation and the vision of the project. Secondly, the production is monitored in order to analyze and detect improvement opportunities. Then, a concept and Functional Design Specification (FDS) are created that include all observations and research that have been done at the facilities. The concept focuses on identifying production improvements that help create a smart production flow that is ready for future innovations.

The first step in a pre-study is to identify the production needs to understand the factory operation and the vision of the project. Secondly, the production is monitored in order to analyze and detect improvement opportunities. Then, a concept and Functional Design Specification (FDS) are created that include all observations and research that have been done at the facilities. The concept focuses on identifying production improvements that help create a smart production flow that is ready for future innovations.

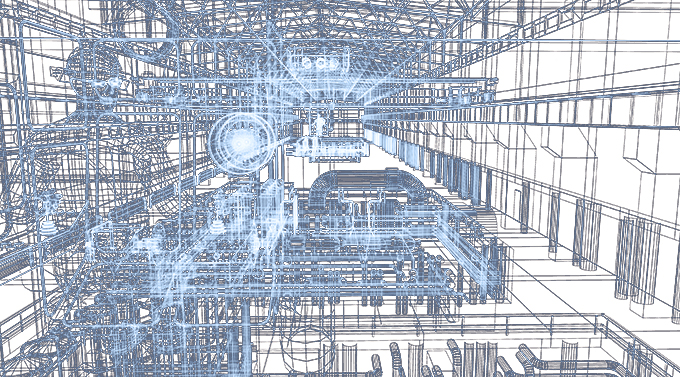

A pre-study can also include visualization of a new solution. This can be done with, for example, a simulation model of the new production environment. The simulation allows for risk-free collaborative tests and experiments based on the available data. Multiple scenarios and metrics can be forecasted simultaneously, and by implementing real-data it is possible to validate the solution by creating a digital twin. This option is a powerful tool to secure new investment. It can be done with relatively small efforts and reduced costs and resources, compared to implementing an untested new solution in the real world.

FlexLink helps you stay competitive in your industry

Pre-studies is becoming increasingly popular in order to stay competitive in every industry. FlexLink’s sales units offer a comprehensive and thorough pre-studies that lead to global and innovative concepts and solutions that reflect the customer’s ideal production plant. Our system architects contribute with skills, experience, knowledge, modern tools and an objective view on how to create a smart production flow.

As one of the few truly global industrial automation companies, FlexLink not only possesses the technical and strategic expertise to conduct the pre-studies but can also implement and support the new solutions with the help of a portfolio of hardware, software/IT and different services. Would you like to redesign an existing production line or plan a new one? We help you conquer your challenges with the right approach, the right instruments, and the right people!

Would you like to know more about pre-studies? Visit our website or ask questions in the comments. Also, read more interesting blog articles on this blog and chat with us on social media!

Leave a Reply