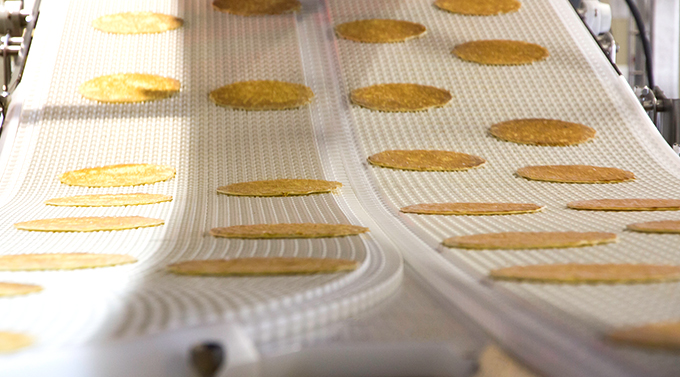

For food production to maintain excellent hygiene, all items in the factory need to be carefully accounted for; everything from the workers’ shoelaces to the lamps in the ceiling. When deciding on which equipment to use, it is crucial to choose production flow solutions that are hygienically designed. A hygienic design not only enables, but simplifies the cleaning process – a procedure that is crucial when producing food.

The right choice of equipment can help reduce contagious microorganisms

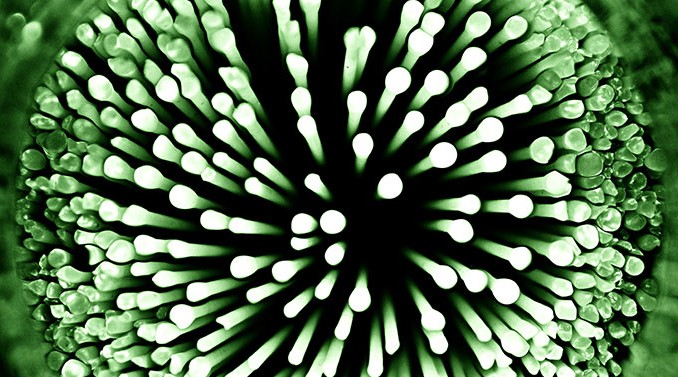

As a food producer, you are responsible for the quality of your products and that the food handling is managed in a correct and hygienic way. The right choice of production equipment can help you along the way. The aim of using hygienic design is to prevent or minimize the risk of exposing consumers to bacteria, toxin, foreign objects and chemicals such as oils and different types of detergents. When designing hygienic equipment there are a number of things to consider. For example, the surface should have a perfect finish so there is no room for microorganisms to grow. The surface should also prevent the build-up of biofilm, be flat and easy to clean. It is important that the equipment is easy to drain without cavities to ensure that all humidity and water vanish.

As a food producer, you are responsible for the quality of your products and that the food handling is managed in a correct and hygienic way. The right choice of production equipment can help you along the way. The aim of using hygienic design is to prevent or minimize the risk of exposing consumers to bacteria, toxin, foreign objects and chemicals such as oils and different types of detergents. When designing hygienic equipment there are a number of things to consider. For example, the surface should have a perfect finish so there is no room for microorganisms to grow. The surface should also prevent the build-up of biofilm, be flat and easy to clean. It is important that the equipment is easy to drain without cavities to ensure that all humidity and water vanish.

Microorganisms change as well as sources of infections

The microorganisms that give us diseases today are not the same microorganisms as previously, since the number of pathogens has increased over the years. Bacteria such as Salmonella, Staphylococcus aureus causing infections and Bacillus cereus causing food poisoning were common prior to the 1960’s. In the seventies, there were a lot of viruses that were contagious through air but also became more and more common in food. Campylobacter causing diarrhea and Yersinia causing flu-like symptoms were also common. In the eighties and nineties, there was an increase of Listeria monocytogenes that causes the infection Listeriosis. The bacterium has had a lot of impact on hygienic design the last years because it creates a biofilm on the surface of the equipment that is hard to get rid of.

The microorganisms that give us diseases today are not the same microorganisms as previously, since the number of pathogens has increased over the years. Bacteria such as Salmonella, Staphylococcus aureus causing infections and Bacillus cereus causing food poisoning were common prior to the 1960’s. In the seventies, there were a lot of viruses that were contagious through air but also became more and more common in food. Campylobacter causing diarrhea and Yersinia causing flu-like symptoms were also common. In the eighties and nineties, there was an increase of Listeria monocytogenes that causes the infection Listeriosis. The bacterium has had a lot of impact on hygienic design the last years because it creates a biofilm on the surface of the equipment that is hard to get rid of.

In earlier years, all infections came from animals and animal products. Today, it is common to get infections like Salmonella, Intestinal bacteria, Hepatitis A and diarrhea when eating for example sprouts, leafy vegetables, berries and sometimes even from drinking water.

Sustainable food production throughout the years

Different efforts have been made to secure a sustainable food production. In the 1980’s it became important to uphold a good hygiene in food production. In the beginning, the main focus was on the fundamental things like keeping track of temperatures, traceability, personal hygiene, education, routines for cleaning and disinfectants. A few years later, the focus changed from controlling the end product to finding the weakest link in the production chain. When entering the twentieth century, it became more and more important to work with the whole food chain. Extensive microbiological risk analyses were conducted all the way from product to consumer.

Different efforts have been made to secure a sustainable food production. In the 1980’s it became important to uphold a good hygiene in food production. In the beginning, the main focus was on the fundamental things like keeping track of temperatures, traceability, personal hygiene, education, routines for cleaning and disinfectants. A few years later, the focus changed from controlling the end product to finding the weakest link in the production chain. When entering the twentieth century, it became more and more important to work with the whole food chain. Extensive microbiological risk analyses were conducted all the way from product to consumer.

Harmless organisms with negative effect vs harmful organisms that go unnoticed

When it comes to food sustainability there are many different quality characteristics to consider; decomposition where food starts to rot, product safety where, for example, minced meat is extra sensitive as well as colour and taste. A certain amount of microorganisms are always present in the food, but the number of organisms can grow. There can be a growing number of lactic bacteria that are harmless but affect the food in a negative way, for example induce a bad smell. Or there can be a growth of pathogenic microorganisms that you are unaware of. The paradox is that the harmless bacteria are often the ones that you can see, or smell, but the harmful bacteria can go unnoticed!

Several factors affect the hygiene result

If you conduct a hygiene sample during production, there will be a clear difference in results from the samples you take in the morning compared to later the same day, since the amount of microorganisms increases gradually over time. A successful design of the equipment can prevent leftovers from sticking, but there are a lot of other factors that also affect the hygiene. What type of food you produce and which requirements the food has on air and temperature, as well as where you are in the production process are examples of factors that affect the hygiene result.

Prevent bacterial growth with hygienically designed equipment

The equipment manufacturer has a responsibility to deliver products that are easy to clean, while the food producer has a responsibility to actually clean the equipment continuously. Since infections from food get more and more common, it is crucial to keep track of your facilities and cleaning routines. Maintaining an excellent hygiene in the food industry is key, both for your business and your customers’ health and safety.

The equipment manufacturer has a responsibility to deliver products that are easy to clean, while the food producer has a responsibility to actually clean the equipment continuously. Since infections from food get more and more common, it is crucial to keep track of your facilities and cleaning routines. Maintaining an excellent hygiene in the food industry is key, both for your business and your customers’ health and safety.

I hope you enjoyed reading about hygienic design within food production. Feel free to contact me with any questions, visit our website and share/comment on the article in social media.

Leave a Reply