In the last few years, the manufacturing industry has seen an increasing interest in elevation solutions. It is based on the need to create line efficiency, an even production flow as well as free up floor space in the production plant. The solutions should be cost-effective and gentle towards the products as well as the environment. In this blog article, I will describe elevation solutions and how they can optimize the production flow in the manufacturing industry.

Moving the production away from the factory floor

There is often a need in the manufacturing industry to free up floor space by moving the production away from the factory floor. This can be done by using elevation solutions that transport products from low level to high level. Generally, these solutions can be used in all manufacturing industries. However, they are not ideal to handle heavy products. Therefore, the solutions are often used in industries such as fast-moving consumer goods (FMCG), healthcare, and pharma, which usually handle lighter products.

The main goals of these solutions are to create line efficiency and an even production flow without downtime or production stops. For example, in the FMCG industry, there is an increasing demand to elevate products and use transportation conveyors on a high level to free floor space for the operators to store material or operate the equipment.

Flexible solutions that can handle products in various sizes

When choosing this type of solution, one must take several factors into consideration, such as how much space is available, how large the budget is, and the complexity of the solution. Another important factor is what type of products should be elevated. Most elevation solutions are flexible and can, for example, handle different products in various sizes.

Line efficiency and even production flow with low product damage

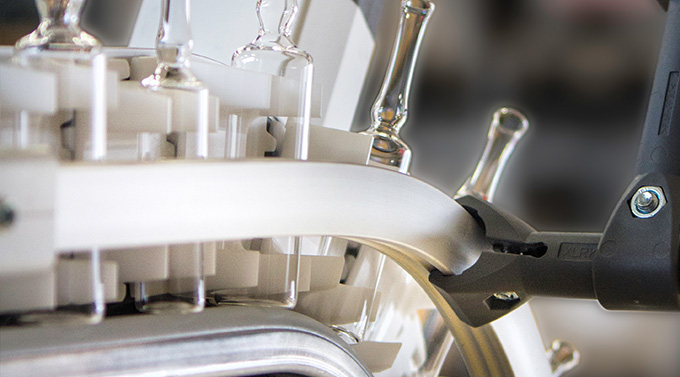

Elevating products must be done in a controlled way to avoid damages to the products. Therefore, it is important to choose the right solutions for the right products. One of the targets with elevating solutions is to allow gentler product handling. Therefore, they are designed so that the products do not have any contact. The solutions contribute to a continuous production flow and often operate at high speeds. Also, they are often driven by low-energy motors, so the actual energy used in transporting the products is relatively low.

Elevating products must be done in a controlled way to avoid damages to the products. Therefore, it is important to choose the right solutions for the right products. One of the targets with elevating solutions is to allow gentler product handling. Therefore, they are designed so that the products do not have any contact. The solutions contribute to a continuous production flow and often operate at high speeds. Also, they are often driven by low-energy motors, so the actual energy used in transporting the products is relatively low.

Spirals, elevators, wedge conveyors and alpine conveyors

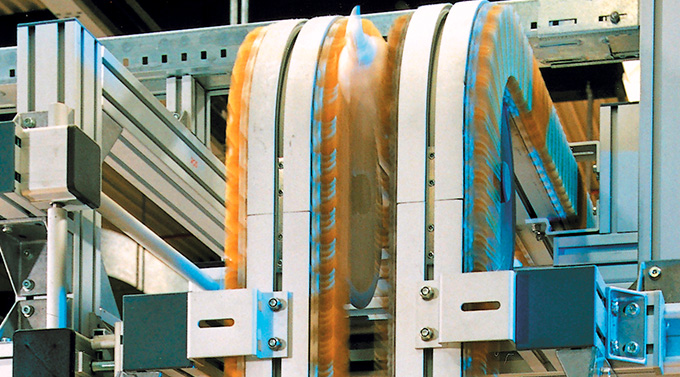

There are several different elevation solutions that are offered to the manufacturing industry, such as spirals, elevators, wedge conveyors, and alpine conveyors. One of the most common solutions is the spiral elevator. It is cost-efficient, energy-efficient, and can go at high speeds. Also, it allows for continuous production flow.

Alpine conveyor

Wedge conveyor

Spiral conveyor

The alpine conveyor and wedge conveyor are less cost-effective compared to the spiral solution but the alpine conveyor has normally a greater capacity and can act as an inline buffer when needed. The wedge conveyor, elevating by gentle clamping the products on the two sides, has a slightly bigger footprint but can go up very high. The least common alternative is the elevator solution. It is similar to a normal elevator and has a workflow where the products must enter the elevator in the right position before it can start its cycle. Therefore, it generally has a lower speed compared to the other solutions. However, it can often handle heavier products compared to, for example, the spiral elevator.

FlexLink provides cost-efficient and innovative elevation solutions

There is constant development regarding elevation solutions in the manufacturing industry. For us, at FlexLink, it is important to stay at the forefront of the development and we are always looking for new and innovative solutions to broaden our product range. For example, we investigate different materials to reduce friction as well as develop our solutions to make them even more cost-efficient. Today, we offer a range of standard elevation solutions as well as develop new, customized solutions together with our customers. There are endless possibilities and ways to optimize the manufacturing industry and we want to be a part of that journey, together with both new and existing customers.

I hope you enjoyed reading my blog article about elevation solutions. Feel free to visit our website for more information about our company and what we offer. Also, pop by our social media channels and our blog for more interesting blog articles.

Leave a Reply