The manufacturing industry is evolving rapidly due to concepts such as connectivity and Industry 4.0. An important part of the development in the industry is the interaction between human and machine. Technologies such as Virtual Reality (VR) and Augmented Reality (AR) open up for the possibility to work proactively and experience production solutions before they are implemented in real life.

New ways to present and experience information

Virtual Reality (VR) generates realistic images, sounds and other sensations that simulate a user’s physical presence in a virtual or imaginary 3D-environment. The effect is commonly created by VR headsets consisting of head-mounted goggles. Everything you do is reflected in the artificial environment. A person using VR equipment is able to move around in the artificial world and interact with virtual features or items.

Another way of presenting information is through Augmented Reality (AR). Augmented Reality is a live direct or indirect view of a physical, real-world environment where some of the elements are “augmented” by computer-generated or extracted real-world sensory input such as sound, video, graphics or GPS data. Augmented reality enhances one’s current perception of reality whereas, in contrast, virtual reality replaces the real world with a simulated one. Augmentation techniques are typically performed in real time and in semantic context with environmental elements, such as overlaying supplemental information, like mounting instructions.

Get a good overview and perception of the end-result early in the process

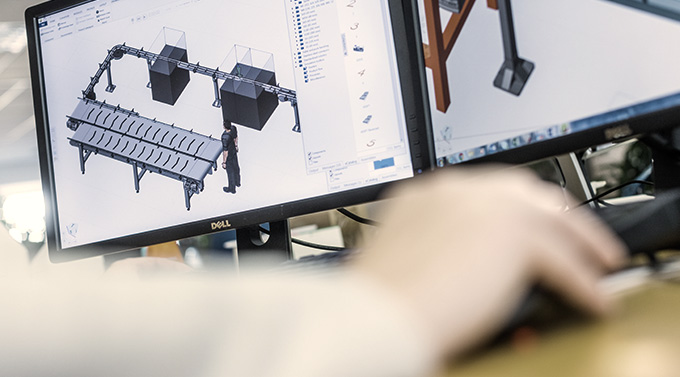

The involvement of VR and AR in the manufacturing industry brings many advantages. The technologies offer the possibility to get a good overview and perception of the end-result early in the process. This enables you to detect possible flaws in the solution before they are there in real life, and before the equipment is mounted. The sooner an e.g. design mistake is detected, the cheaper it is to adjust it. This will decrease the commissioning time and save money for all parties involved. The technologies are user-friendly and offer a good and efficient way to communicate and exchange information in a very educational manner. This gives you a good tool to explain complex problems and solutions. In addition, they help when planning the layout of the production line since the artificial world gives a better and clearer understanding of the concept compared to, for example, a drawing made in a CAD program. The customer will be able to experience the new solution in VR before it exists. Or the solution could be visualized in an existing factory utilizing AR technology.

The involvement of VR and AR in the manufacturing industry brings many advantages. The technologies offer the possibility to get a good overview and perception of the end-result early in the process. This enables you to detect possible flaws in the solution before they are there in real life, and before the equipment is mounted. The sooner an e.g. design mistake is detected, the cheaper it is to adjust it. This will decrease the commissioning time and save money for all parties involved. The technologies are user-friendly and offer a good and efficient way to communicate and exchange information in a very educational manner. This gives you a good tool to explain complex problems and solutions. In addition, they help when planning the layout of the production line since the artificial world gives a better and clearer understanding of the concept compared to, for example, a drawing made in a CAD program. The customer will be able to experience the new solution in VR before it exists. Or the solution could be visualized in an existing factory utilizing AR technology.

The process of performing service and maintenance can also be more efficient since the artificial environment facilitates the communication between the operators and the technicians. The technologies contribute to erasing geographical barriers and, in some cases, allow for service and maintenance to be performed without any service technician having to physically visit the production site. A virtual world also allows for a lot of tests and verifications on the production equipment, which facilitate the installation process.

Accessible and cost-effective technologies that improves your production

The future for VR and AR in the manufacturing industry looks very bright. The technologies are both accessible and cost-effective and they will develop even more in the years to come. More and more professionals working in the manufacturing industry are interested in the technologies and how they can be used to optimize their production. The equipment today is adjusted for people’s living rooms and the primary area of use is in the gaming industry. Since the gaming industry has driven the development it has lead to a cheap and user-friendly technology. The question is if there will be a future need for equipment that is adjusted to an industrial environment, depending on the area of use.

The future for VR and AR in the manufacturing industry looks very bright. The technologies are both accessible and cost-effective and they will develop even more in the years to come. More and more professionals working in the manufacturing industry are interested in the technologies and how they can be used to optimize their production. The equipment today is adjusted for people’s living rooms and the primary area of use is in the gaming industry. Since the gaming industry has driven the development it has lead to a cheap and user-friendly technology. The question is if there will be a future need for equipment that is adjusted to an industrial environment, depending on the area of use.

Improve your production results by experiencing new products and solutions

In the latest version of FlexLink’s Design Tool, we have the possibility to export our design to a VR environment. As a supplier of factory automation solutions, we value using the latest technologies and methods to deliver high-quality production equipment. VR and AR bring great value to our customers as it facilitates the communication during the whole process. In addition, using virtual equipment early in the process helps to avoid costly errors. It also brings value to our customers as it helps them to experience new products and solutions as well as learn about their production line and how it can be improved.

What are your experiences of using VR and AR in the manufacturing industry? Feel free to share your comments in the comment field below. Would you like to know more about FlexLink and our solutions you are welcome to visit our website, our smart factory blog as well as our social media channels.

Leave a Reply