A production line in the manufacturing industry needs to live up to various demands and expectations from different customers. However, there are some aspects that every producer of fast moving consumer goods needs to keep in mind when investing in a new line. In this blog article, I will share some valuable tips on how to maximize the production efficiency right from the start.

A smart workflow is crucial to achieve maximal output

There is a predominant need to increase efficiency and improve the overall equipment effectiveness (OEE) within the production industry. It is fairly common, when investing in a new production line, to mainly focus on the purchase of the machines. Linking the processes together, as a complete line, is not given the same priority. A smart workflow is required to achieve maximal output, to ensure that the investments are protected.

4 tips on how to increase output

High efficiency often means a high return on investment. But to gain efficiency, you need to avoid the most common mistakes when investing in a production line. Here are 4 tips:

1. Conduct a proper analysis and simulation of your upcoming line

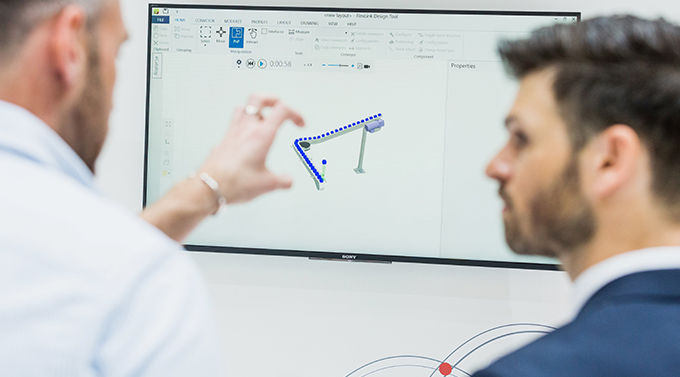

The first thing you need to do is to create a clear view of how your upcoming production line will work, including the flow of consumables and operator work pattern. If you conduct an analysis from start, by using simulation and animations, you ensure a maximum use of the machines and thereby obtain a high return on investment. You should conduct the initial analysis before choosing supplier and machines. The analysis process consists of either a mapping of an existing line, or the use of theoretical data if the machines are not available for analysis. You should also have one party responsible for the simulation to ensure that you get correct and sufficient information from all the machine suppliers. The granularity of each machine is determined by previous experience of that particular machine to safeguard the simulation result.

The first thing you need to do is to create a clear view of how your upcoming production line will work, including the flow of consumables and operator work pattern. If you conduct an analysis from start, by using simulation and animations, you ensure a maximum use of the machines and thereby obtain a high return on investment. You should conduct the initial analysis before choosing supplier and machines. The analysis process consists of either a mapping of an existing line, or the use of theoretical data if the machines are not available for analysis. You should also have one party responsible for the simulation to ensure that you get correct and sufficient information from all the machine suppliers. The granularity of each machine is determined by previous experience of that particular machine to safeguard the simulation result.

2. Create general control architecture of the production line

When working with your design-reviews, it is important to focus just as much on the control architecture as the mechanical solution. You should request from the supplier that all the machines’ states should be defined in the same way. That means that you can conduct better data for analysis of production improvements, gain an easier maintenance process as well as integrate new future machines in an easy consistent way.

When working with your design-reviews, it is important to focus just as much on the control architecture as the mechanical solution. You should request from the supplier that all the machines’ states should be defined in the same way. That means that you can conduct better data for analysis of production improvements, gain an easier maintenance process as well as integrate new future machines in an easy consistent way.

If you work with standardization, you increase the chance to to produce more products. An excellent monitoring over the line performance, helping you to find next production efficiency improvement. In the start-up phase, it is important to be just as skilled at writing requirement specifications as writing mechanical specifications. Over all, it is important to have a strict control over the architecture of the programming to make sure that the communication between the machines work.

3. All interfaces of a production line need to have a clear ownership

A clear ownership contributes to the whole production line being more effective and ensures that the production line will reach the capacity it is designed for. This means that the plants can produce more products with a reduced risk of disturbances, and ultimately gain better OEE. If problems would occur, with for example a start-up, an indefinite ownership means that it is unclear who will take responsibility and you as a customer will suffer. Therefore, it is important to involve the supplier of automated production flow solutions early in the process. This enables a clear dialogue between the machine supplier and production flow supplier. A close cooperation in the implementation process can lead to the machines being adjusted according to the overall product flow, which means that all interfaces become well defined. This brings a holistic approach that results in a better production line in the end.

A clear ownership contributes to the whole production line being more effective and ensures that the production line will reach the capacity it is designed for. This means that the plants can produce more products with a reduced risk of disturbances, and ultimately gain better OEE. If problems would occur, with for example a start-up, an indefinite ownership means that it is unclear who will take responsibility and you as a customer will suffer. Therefore, it is important to involve the supplier of automated production flow solutions early in the process. This enables a clear dialogue between the machine supplier and production flow supplier. A close cooperation in the implementation process can lead to the machines being adjusted according to the overall product flow, which means that all interfaces become well defined. This brings a holistic approach that results in a better production line in the end.

4. Focus on how the production line will be operated

When implementing a new production line, it is important to consider the operators who will be working with the production. How can the production line be as effective as possible, and how can the production line be designed in an optimal way for the personnel working with it? The production line should be easy to work with, it should be easy to clean and easy to extend, and there should be good access to all the machines.

When implementing a new production line, it is important to consider the operators who will be working with the production. How can the production line be as effective as possible, and how can the production line be designed in an optimal way for the personnel working with it? The production line should be easy to work with, it should be easy to clean and easy to extend, and there should be good access to all the machines.

A way to incorporate this mindset, is to create a clear vision of how the factory should work and what it should accomplish. It is important to include the operators as well as hygiene experts from the beginning. All parties’ questions must be answered during the quotation stage, before the equipment is in place. This goes hand in hand with building production lines with excellent quality and good hygiene. A production line should have a clear concept from process to palletizing, which contributes to both efficiency and a higher output. If the implementation of the production line is consistent, it will also benefit the operators. It will lead to more motivated personnel doing a better job, which in the end leads to more production.

FlexLink delivers flexible and customized automated production flow solutions

There are different challenges and needs in a production depending on where you are in the world, that your supplier of automated production flow solutions need to adapt to. Generally, flexibility and fast changeovers are important to be able to respond quickly to variations in sales. No matter where you are in the world, your production line must be adjustable to fit your needs.

FlexLink can be your integration partner taking responsibility of the production flow in complete production lines, as well as ownership over the interfaces that connect the machines together. That enables us to guarantee that the production line will function in a desired way. It becomes very clear who has the responsibility of the interfaces, which is invaluable for the customer. FlexLink is a flexible provider of automated production flow solutions that design your production line based on your specific needs.

Hopefully, you gained some valuable information from reading my article. Contact me if you come up with any questions, and visit our website to learn more about FlexLink. I look forward to discussing the article with you in our social media channels.

I agree that you’d want a clear view of how your production line will work before you try to implement it. I definitely want to make sure that my line is going to be the most effective it can be. I wonder what the best way to organize it would be.