ProPak Asia is the largest processing and packaging exhibition in Asia and took place in Bangkok from the 12th-15th of June this year. It’s Asia’s most important platform for connecting the region’s rapidly expanding processing and packaging industries. We asked visiting food manufacturers about their current requirements for suppliers and the manufacturing trends they are seeing. This article is a snapshot of their answers.

Food safety – the major concern

Food safety is increasingly in the spotlight both around the world and for Asian food manufacturers. Compliance with food standards and regulations is a critical aspect of the production and packaging of food. It ensures a safe product for consumers, limits the number of recalls and increases the chance of producers to gain certification for food exports. These standards provide specifications and guidance for the production and delivery of services. In doing this, quality and reliability are maintained whilst market issues such as acceptance and access are more easily handled. One example of these standards is ISO 22000 Food Safety Management Systems. This focuses on product integrity and covers food ingredient manufacturing, processing, and packaging. Another standard is the BRC Global Standard for Packaging that covers the safety of materials for consumers. Overall, these standards ensure that efficiency and safety are maintained throughout the value chain.

The regulations and standards governing food safety around the world are becoming ever more strict and complex. This change is having the knock-on effect of accelerating technological development for food safety, whilst the adoption of current technologies is likewise increasing. If production and trade are to be safeguarded, it is essential that food producers and manufacturers in Asia adapt to these new developments with technology.

Increased requirements from suppliers

The importance of a clean, hygienic production environment increases considerably when handling un-packed food in wet and even dry environments. Failure to meet these requirements can result in extreme measures such as a product recall or even worse outcomes such as consumer illness, which would have a major impact on both brand image and the bottom line. Food processors rely on high hygienic standards in their processes to prevent the growth of harmful bacteria in products. The consumer demands for longer shelf life and more natural products increase the potential for microbial contamination in food products if the high hygienic standards are not maintained.

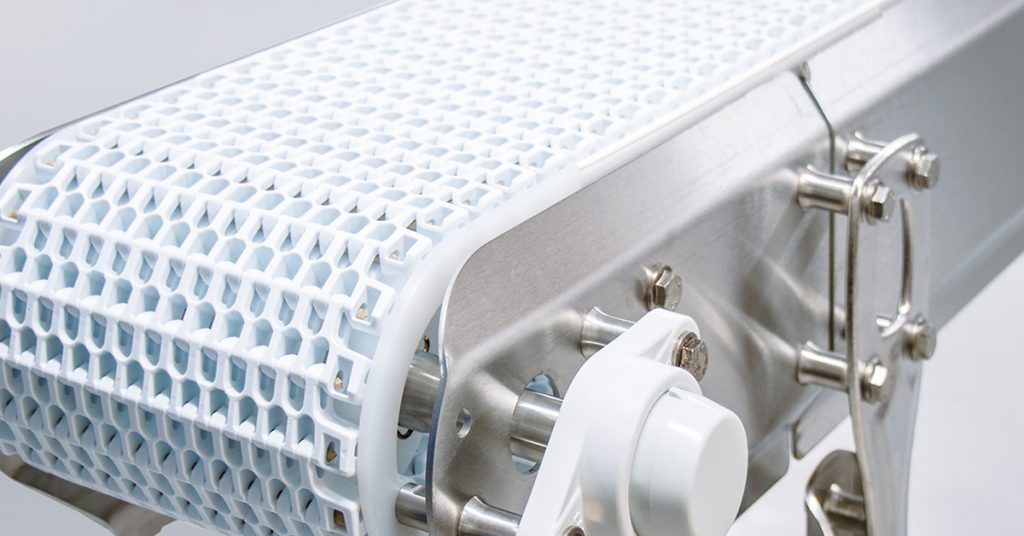

A basic requirement highlighted during the interviews with manufacturers was that conveyors and packaging machine equipment should be constructed using stainless steel. This is stronger and more resistant to surface damage, making it a superior choice when effective cleaning and sanitizing are a high priority. Over a period of time, it is not possible to prevent aluminum from corroding and it will always need to be replaced. But just considering the material is not enough. The equipment design has to be hygienic and should follow current standards and regulations like EHEDG and 3-A SSI. For example, a simplified, hygienic conveyor design increases ease of cleaning as well as reducing downtime and overall costs, with a positive impact on the bottom line. The crevice-and cavity-free design eliminates most of the areas that are difficult to clean. With small contact surfaces between component parts, no open threads, no sharp corners and no flat horizontal surfaces, a repeatable and consistent cleaning result are also ensured.

The popularity of drum-motor drive technology is another example. External gear motors traditionally power belt-conveyors systems; however, drum-motors offer significant benefits because the drive mechanism is completely enclosed in a crowned stainless steel or cylindrical steel shell with caps and seals at each end. With this design, the drive components are protected from contaminants, which is a huge plus for food production where hygiene is so important. The motor is also easier and more cost-effective to fit, service and clean because of the sealed case.

Crevice-and cavity-free design

Integrated industry 4.0 in food processing

Industry 4.0 is shaking up how operations are handled by food processors whilst new technology developments and consumer preferences are the other major changes. An increase in digital connectivity throughout all phases of the processing and packaging production lines is creating benefits that are widely recognized by many organizations. Fast adoption of digitalized automation with industry 4.0 is helping food operators enhance their operations and accelerate productivity. Optimizing processes will lead to leaner production methods and more intelligent factories. These innovations are another step in the transformation of the food industry.

We hope you enjoyed reading our blog article about trends in the food production industry in Asia. Do you see other trends? Feel free to comment on the article.

Would you like to know more about FlexLink’s battery production automation solutions? You are always welcome to contact us or visit our website. To never miss out on any of our blog posts, keep an eye out on this blog and follow us on LinkedIn or Twitter. We will continue to share our knowledge in industrial automation and production efficiency with you.

Leave a Reply