To be attentive and adaptable to new technology, are a prerequisite when operating in the fast moving business of the production and packaging industry. The industrial revolution 4.0 pitches robotics, networked data collection and analytics as the next wave of efficiency, and is a prime example of a concept to keep track of. In this blog article, I will dive into the world of the fourth industrial revolution.

The fourth industrial revolution promotes the computerization of manufacturing

The term Industry 4.0, or the fourth industrial revolution, was first used in 2011 in Germany, and is today a topic that is high on the factory automation industry’s agenda in most industrialized countries. Industry 4.0 facilitates the “smart factory” and is a collective term covering future oriented individualized automation, deep learning and smart technologies, new services and people development concepts. The first industrial revolution mobilized the mechanization of production by using water and steam power. The second one introduced mass production with the help of electric power, followed by the third digital revolution and the use of electronics and IT to further automate production. With the fourth revolution, intelligent networks along the entire production chain can control each other autonomously by connecting different machines, workpieces and systems and be their “digital twin”.

Industry 4.0 represents a paradigm shift from centralized to decentralized smart manufacturing and production. It is enabled by intelligent ICT-based machines (Information and Communications Technology), systems and networks, which are capable of independently exchanging and responding to information to manage industrial production processes. This entails new models for businesses and cooperations between companies and institutions.

Total integration between workshop floor, supply chain and business systems

By following the concept of Industry 4.0, manufacturing systems will move toward total integration between the workshop floor, the supply chain and different business systems. It will create flexible machinery for instant change of product, format and throughput, as well as a seamless interaction of operators, robotics and machinery. Industry 4.0 will also contribute to the development of smart manufacturing plants and new technologies in open platforms, which is where many companies base their new productions.

The industrial revolution 4.0 enables layouts with smart conveying

FlexLink sees good prospects with involving Industry 4.0 in their automated production flow solutions. The concept enables dynamic production capacities and layouts with smart conveying. The connection of data and flow will be more intelligent when it comes to both the manufacturing process and the end product. It will also open up for new materials and packaging with a more frequent interaction between processes and products throughout the production chain.

FlexLink has a high level of readiness when it comes to Industry 4.0

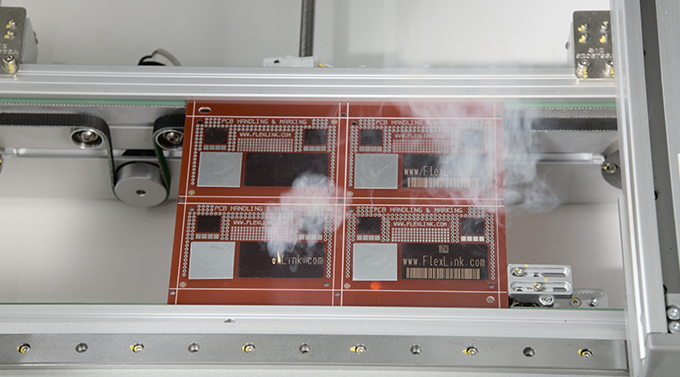

For FlexLink, Industry 4.0 impacts the business, as well as the organizational and technological development. FlexLink has a high level of readiness and we are constantly adding elements of Industry 4.0 in our solutions. We can also refer to a history of products and solutions that are supporting the elements of Industry 4.0. It includes line monitoring, equipment monitoring, intelligent components with integrated controls, mixed manual and automated production, modular production line elements and engineering tools connecting physical and virtual reality. We have primarily delivered these solutions to the electronics, automotive, optical and medical device industries.

For FlexLink, Industry 4.0 impacts the business, as well as the organizational and technological development. FlexLink has a high level of readiness and we are constantly adding elements of Industry 4.0 in our solutions. We can also refer to a history of products and solutions that are supporting the elements of Industry 4.0. It includes line monitoring, equipment monitoring, intelligent components with integrated controls, mixed manual and automated production, modular production line elements and engineering tools connecting physical and virtual reality. We have primarily delivered these solutions to the electronics, automotive, optical and medical device industries.

FlexLink focuses a lot on staying updated in the technological field to deliver excellent automated production flow solutions to our customers. One of our most important jobs is to offer a solution that increases the quality of our customers manufacturing and production processes, a job we take very seriously.

FlexLink focuses a lot on staying updated in the technological field to deliver excellent automated production flow solutions to our customers. One of our most important jobs is to offer a solution that increases the quality of our customers manufacturing and production processes, a job we take very seriously.

I hope you enjoyed reading my article, and that you learned something new. If you have any questions, don’t hesitate to visit our website or contact me directly. See you on social media!

Leave a Reply