Automated end-of-line solutions can be described as the final piece of the puzzle to a fully automated packaging line. There are two types of end-of-line solutions corresponding to two types of philosophies; centralized and decentralized end-of-line. In this article, I dig into the concept of end-of-line, describing the differences between the two philosophies and giving you examples of the different end-of-line solutions.

End-of-line automation becomes an integral part of companies’ investment plans

End-of-line automation is a trend that is catching up as companies realize its importance and make it an integral part of their investment plans. Rising labour cost, higher employee turnover, and faster line speeds along with other issues are pushing management to automate and upgrade existing production lines, and consider new lines with full automation.

What is end-of-line?

Product packaging can be categorized into primary packaging, secondary packaging, and tertiary packaging. End-of-line solutions typically cover the tertiary packaging and involve the steps where the products are prepared for shipment. Automated end-of-line solutions may include stand-alone applications or complex systems including equipments such as palletizers, robots, conveyors, accumulators, printers, readers, dispensers for pallets and sheets, and wrappers.

The difference between centralized and decentralized end-of-line solutions

In plants with multiple packaging lines, there are two alternatives for palletizing products: a single large central palletizer drawing products off of several lines, or a decentralized concept which is dedicated palletizing cells located at the end of each packaging line.

In two recent projects, FlexLink delivered two complete end-of-line solutions meeting the two main philosophies.

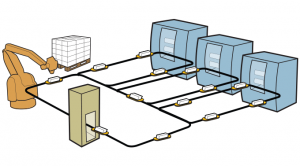

Centralized concept

A manufacturer of private label diapers chose the centralized concept where the end-of-line palletizing is located in a separate area to serve four lines. The main arguments were space constraints and to maximize the use of the palletizing equipment. In this case, the operator teams have a functional responsibility for the palletizing of the whole factory output. A solution like this can have a higher productivity than a decentralized solution, and has advantages from a maintenance point of view. But the factory can at the same time be more sensitive to equipment failures.

A manufacturer of private label diapers chose the centralized concept where the end-of-line palletizing is located in a separate area to serve four lines. The main arguments were space constraints and to maximize the use of the palletizing equipment. In this case, the operator teams have a functional responsibility for the palletizing of the whole factory output. A solution like this can have a higher productivity than a decentralized solution, and has advantages from a maintenance point of view. But the factory can at the same time be more sensitive to equipment failures.

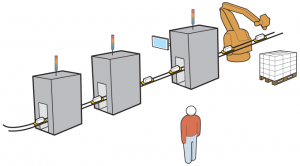

Decentralized concept

The second example is from a producer of hygiene products, applying the decentralized concept where one end-of-line solution is connected to two adult diaper production lines. Products are handled in cases, trays (display packaging) and bundles. The major reason for choosing this concept is to have the operator teams responsible for the entire line and having a good overview of the whole process from converting to packaging and palletizing.

The second example is from a producer of hygiene products, applying the decentralized concept where one end-of-line solution is connected to two adult diaper production lines. Products are handled in cases, trays (display packaging) and bundles. The major reason for choosing this concept is to have the operator teams responsible for the entire line and having a good overview of the whole process from converting to packaging and palletizing.

Both lines are delivered turn-key and include quality control, conveying, elevation, manipulation and dynamic accumulation solutions for minimizing line downtime. The palletizing cells manage different pallet sizes and optimize the layers for maximizing the use of the ready pallet.

Centralized or decentralized end-of-line?

Choosing a centralized or decentralized end-of-line solution should ultimately come down to what solution works best for your main production philosophy. At the end of the day, the goal should always be to provide equipment that offers great reliability and seamless integration of the entire production, whether it involves centralized or decentralized end-of-line solutions.

Choosing a centralized or decentralized end-of-line solution should ultimately come down to what solution works best for your main production philosophy. At the end of the day, the goal should always be to provide equipment that offers great reliability and seamless integration of the entire production, whether it involves centralized or decentralized end-of-line solutions.

Do you agree with me? Should the choice be made based on business model, or something else? Let me know in the comments!

Also feel free to contact me with any questions. If you want to know more about our automatized production flow solutions, visit the FlexLink website. We have in-depth know-how of handling of products – from primary packaging to the end of line. No matter which concept we apply; centralized or decentralized, we always take into consideration the specific requirements of the production processes.

Leave a Reply