Depending on the situation, friction could be experienced as either positive or negative. When pulling out a kitchen drawer you want as little friction as possible, but when it comes to friction between the tires on your car and the road – friction can save lives. In the manufacturing industry, friction can be both a positive and a negative thing.

Friction – a combination of inter-surface adhesion, surface roughness, surface deformation and surface contamination between two touching surfaces

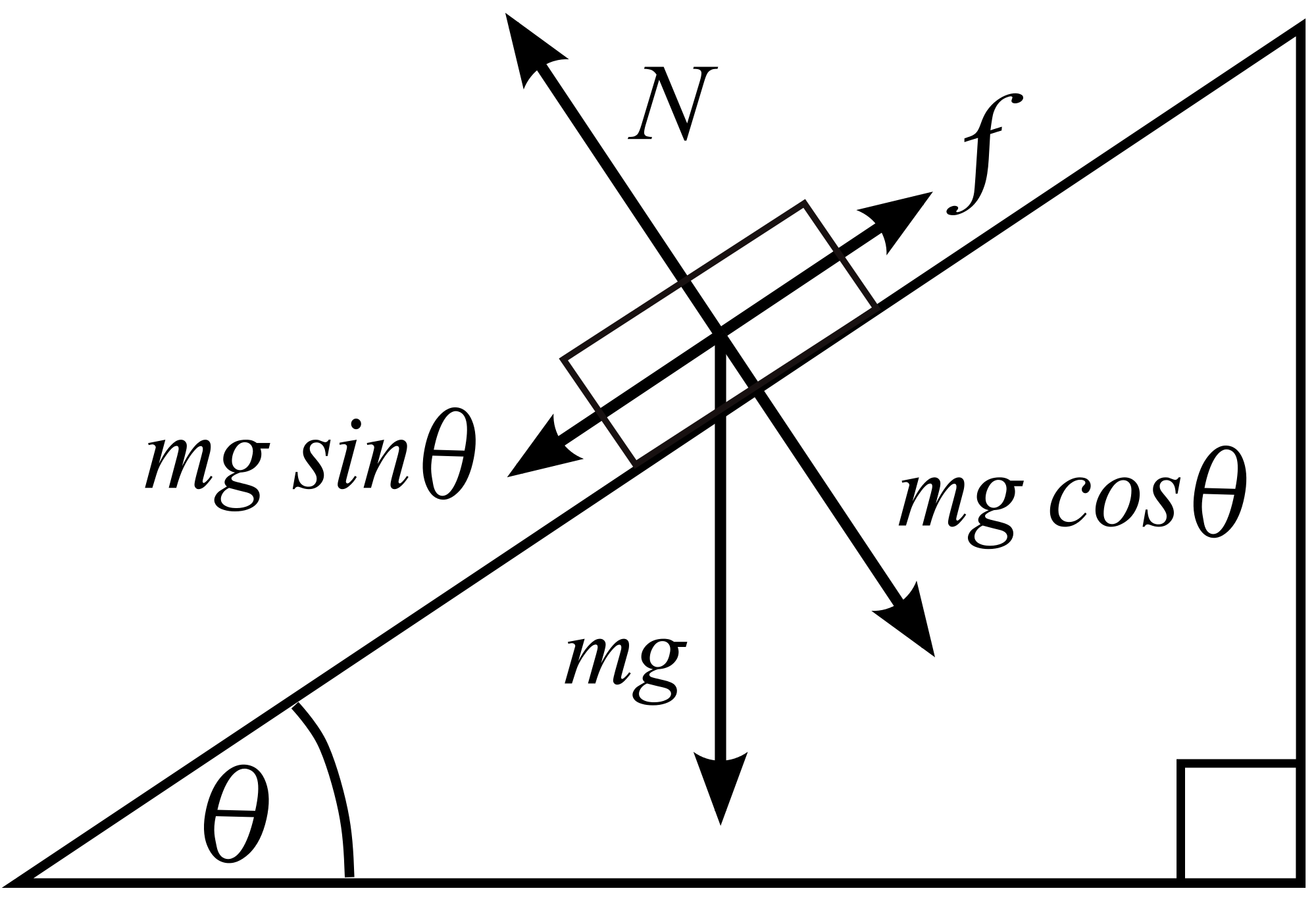

Friction is what you call the force resisting the relative motion of solid surfaces sliding against each other. Factors that affect friction are force, speed, surface roughness, adhesion, lubrication, contamination and temperature, to name a few. It is not a fundamental force, but a result of the resistance between two touching surfaces. The coefficient of friction is a dimensionless value, which describes the ratio of the force of friction between two bodies and the force pressing them together. The coefficient of friction cannot be calculated, but has to be measured in real tests with combinations of different materials. Some materials generally have a low coefficient of friction against most materials, for example ice, and some have a high, for example rubber.

Friction is what you call the force resisting the relative motion of solid surfaces sliding against each other. Factors that affect friction are force, speed, surface roughness, adhesion, lubrication, contamination and temperature, to name a few. It is not a fundamental force, but a result of the resistance between two touching surfaces. The coefficient of friction is a dimensionless value, which describes the ratio of the force of friction between two bodies and the force pressing them together. The coefficient of friction cannot be calculated, but has to be measured in real tests with combinations of different materials. Some materials generally have a low coefficient of friction against most materials, for example ice, and some have a high, for example rubber.

Dry friction vs lubricated friction in automated production flow solutions

High and low friction are equally relevant in a production line. On the sliding surfaces of a conveyor, low friction is required since high friction makes the movement harder, requiring more energy which creates more heat and wear. However, on the transporting surfaces of a conveyor belt, high friction is often preferred to secure the stability of the products being transported.

High and low friction are equally relevant in a production line. On the sliding surfaces of a conveyor, low friction is required since high friction makes the movement harder, requiring more energy which creates more heat and wear. However, on the transporting surfaces of a conveyor belt, high friction is often preferred to secure the stability of the products being transported.

There are two main types of friction considered in the manufacturing industry; dry friction and lubricated friction. Dry friction is the relative motion between two dry surfaces, compared to lubricated friction, which occurs when the sliding surfaces are separated by a lubricant. Thus, the surfaces are only in contact with the lubricant and lose contact with each other, leading to low friction saving energy and wear. However, lubricated friction can cause contamination on the products if they come in contact with the lubricant.

There are just as many friction values as there are material combinations

There is no such thing as a specific frictional force for a specific material. Friction is something that occurs between two materials and varies depending on different circumstances, such as material combination. If you drag a piece of plastic against certain fluoropolymers the friction will be minimal, compared to if you drag the same plastic against concrete where the rough surface adds to the friction. Additionally, circumstances like force, speed, surface roughness and temperature will influence the actual friction. Consequently, each material combination must be tested before knowing what type of friction that combination will generate in a given situation. However, by adding additives to materials, the frictional force between two materials can be altered. Oil can be added to achieve a lower friction between two plastic materials, and a rubber substance may in turn increase friction. Often, but not always, high friction equals high wear.

FlexLink adjusts friction to fit specific production lines

FlexLink has years of experience in calculating and adapting the right friction to the right production flow solution. Different plastic materials affect the friction in different ways, and we continuously test different material combinations to achieve the exact right combination to fit your production’s specific needs. In our test labs, we conduct numerous tests where we investigate durability, energy consumption, wear and noise level, among other things. FlexLink also work in close collaboration with Swerea, one of the leading science institutes in Sweden, to get cutting edge expertise in how to develop and test different plastic combinations. When deciding on what type of friction that is required, we always take into account external factors affecting the friction, such as humidity, dust and dirt. One might be shocked over the impact friction has on a production process, and how many ways there are to adjust friction. FlexLink customizes automated production flow solutions to fit your specific needs, and the friction coming with the solutions is no exception.

What are your thoughts on friction and its impact on the manufacturing industry? Please let me know in the comments below. You are welcome to visit our website for more information, or contact me with any questions. Don’t forget to visit our blog for more interesting blog articles!

Leave a Reply