Our food habits change as globalization is increasing, the geographical distance is getting smaller, and a lot of people are getting a more active and time-consuming lifestyle. In this blog post, I will discuss the importance of hygiene in the production process, how the production process has changed, and which production trends that can affect the durability of food.

Today we produce food in a different way, compared to a few generations ago

The food materials, which are the basis of our food, have basically stayed the same for thousands of years. However, how we handle the food materials have changed significantly. Today, we produce very complex food. We mix many different raw materials and turn them into one product. We produce a lot of processed and packaged ready-to-eat food that is easily portable and has a long shelf life. In general, we produce more and more food, and the demands on speed and efficiency in the food production are extremely high.

High demands on hygiene and food safety in the production process

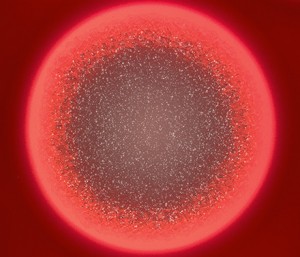

More people are becoming sensitive to microorganisms. Living microorganisms such as bacteria, fungi and virus are found everywhere, including in food. Microorganisms are too small to be seen with the naked eye, but they are visible under a microscope. Some of them are harmless, but some are harmful and can cause diseases. A person can get sick by being exposed to only a few microorganisms, and this puts extremely high demands on hygiene and food safety in production. It is crucial to keep the equipment and environment in the factories clean in order to eliminate harmful microorganisms and to avoid bacterial growth, as well as to minimize the risk of infection.

Production trends that require high quality and hygiene on the products

As our relationship to food changes, the quality and hygiene of the food need to adapt accordingly. There are a number of production trends that affect the way we work with quality and hygiene in food production. RTE-products (Ready-To-Eat) are getting more and more common, where some of the products require long durability. Since the products are prepared, they are often very sensitive and responsive to microorganisms. A goal that many producers have is to be able to store the RTE-products in room temperature. This means tremendous demands on hygiene, since microorganisms thrive in warm temperature, and it only takes a few microorganisms to make a product inedible. Therefore, it is important to have excellent hygiene in the production, to secure a high quality of the products.

Centralized production means having one main facility from which the food is transported and distributed. This makes the process of ensuring quality more easy, since there only is one process that needs to be validated, but it also poses a risk since many people could get sick if something went wrong. Long transportations can expose the food to a lot of bacteria. At the end of the transportation line, the products may require some sort of processing, which is a source of variability. Therefore it is required that the products maintain a high quality during the whole transport, until they reach the consumers.

Increasing demands on hygiene due to extra sensitive consumers

Another aspect to achieve a good hygienic production process is an increasing amount of population that qualify as extra sensitive. Today, about 20 percent of the population belong to the risk group of being extra sensitive. Those who qualify in that group are elderly people over 65 years old, people that have gone through a transplant, people with a suppressed immune system, pregnant women and infants.

Another aspect to achieve a good hygienic production process is an increasing amount of population that qualify as extra sensitive. Today, about 20 percent of the population belong to the risk group of being extra sensitive. Those who qualify in that group are elderly people over 65 years old, people that have gone through a transplant, people with a suppressed immune system, pregnant women and infants.

Factors that affect the durability of food during the production process

There are many factors to consider when producing and transporting food, that will determine if the food will have a long durability. Already from the beginning, there is a certain amount of microorganisms in the products that will be affected during the production process. It is therefore important to continuously control the products to determine if the food contains a lot of microorganisms and what type it is, as some are harder to eliminate than others. The effectiveness of the production process is important, since it is possible to eliminate some of the microorganisms during production. This happens for instance in the process of pasteurizing milk. Reinfection cause one fourth of all pathogenic outbreaks. Reinfection can be avoided by keeping an excellent hygiene on the surfaces that come in contact with the food during production. That will help to eliminate a proliferation of contagious microorganisms.

There are many factors to consider when producing and transporting food, that will determine if the food will have a long durability. Already from the beginning, there is a certain amount of microorganisms in the products that will be affected during the production process. It is therefore important to continuously control the products to determine if the food contains a lot of microorganisms and what type it is, as some are harder to eliminate than others. The effectiveness of the production process is important, since it is possible to eliminate some of the microorganisms during production. This happens for instance in the process of pasteurizing milk. Reinfection cause one fourth of all pathogenic outbreaks. Reinfection can be avoided by keeping an excellent hygiene on the surfaces that come in contact with the food during production. That will help to eliminate a proliferation of contagious microorganisms.

A correct production process to avoid bacterial growth during production

When studying bacterial growth in a growth curve, there are different elements in the process that will influence how the bacteria develop and how fast it will happen. Time is an important factor for bacterial growth, since the microorganisms grow depending on how much time it gets to thrive. Temperature, water, salt, sugar and fat are also factors that either prevent or enable bacterial growth.

I hope you enjoyed the second part of my article series about bacterial growth and how to avoid it. If you have any questions, please visit FlexLinks website or contact me directly. Keep an eye out for the third article that will focus on hygienic design.

Leave a Reply