Ensuring a safe production line is of prime importance in the food industry. Designing a hygienic line guarantees high-quality food production and safeguards your brand by mitigating the risk of recalls.

Minimizing the risk of food contamination, bacterial growth, and even accidents during the process all contribute to safe food production. If you do not take this seriously, you risk both the health of your consumers and your brand’s health.

“Simply put, the food you produce should only contain the ingredients you intended,” says Tommy Karlsson, Director of Strategic Business Units for Europe North & East at FlexLink AB.

FlexLink has been working with automation solutions for almost 45 years and has extensive knowledge and experience in providing food conveyor systems and material flow solutions for the entire production line. The food industry is an area where FlexLink has a strong background, with a focus on high-quality production processes that ensure the safety of the food produced.

How equipment design reduces bacterial growth

“There are many ways to create a safe work environment”, explains Tommy. “Through hygienic food processing equipment design, you can reduce the risk of bacterial growth and cross-contamination.”

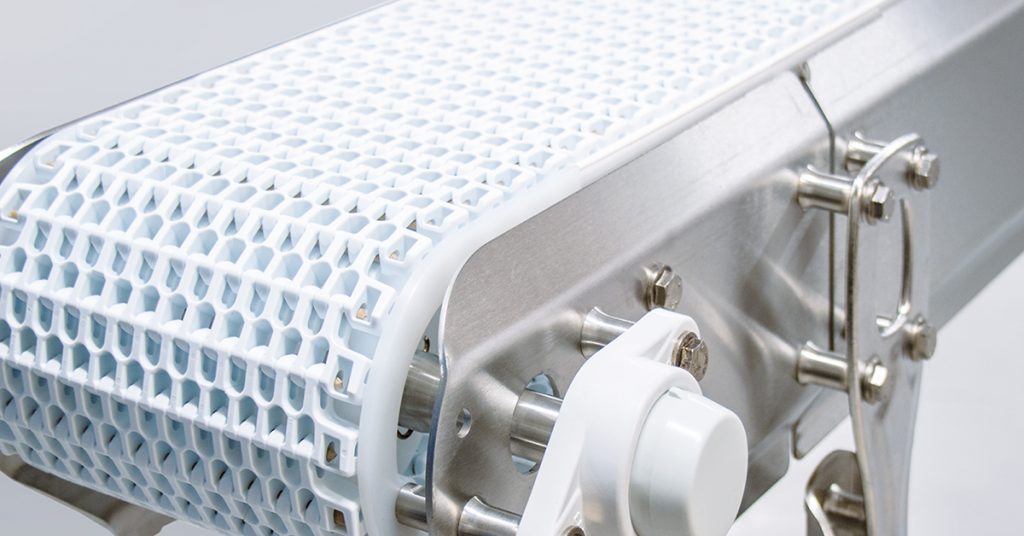

“Our equipment has been designed to make cleaning easy without leaving behind a trace of cleaning chemicals or bacteria. Avoiding sharp corners on the line allows water used when cleaning to reach the whole conveyor, and having space between components reduces surface tensions where chemicals and liquids left behind can encourage bacterial growth.”

“We avoid cavities in the production line because this is where bacteria thrive, making it difficult to guarantee that it is clean. Instead, we work with open solutions, where operators can easily see the results. We also avoid horizontal surfaces, which take a long time for any remaining cleaning liquid to dry. Finally, by making the line easy to handle for the operators, the risk of injury is reduced, a high priority for FlexLink during line design”, says Tommy.

The traceability trend continues

Today, consumers are more conscientious than ever about the origins and journey of their food products. On the one hand, the consumer sets higher demands to know exactly where food comes from; on the other, it is important to distinguish between batches if something needs to be withdrawn. Regulatory bodies and industry standards continue to tighten, reinforcing the imperative for meticulous traceability protocols. Amidst concerns over foodborne illnesses and contamination, the ability to swiftly trace back the origins of a product becomes not just a desirable feature but an absolute necessity.

Manufacturers must maintain precise records and systems to track each component, ingredient, and process throughout the production chain. This ensures compliance with regulatory requirements and the swift execution of recalls when necessary, minimizing risks to public health and brand integrity. Therefore, traceability serves as a linchpin for quality control and process optimization within food production facilities

Tommy concludes: “Through creating a clear structure in the product line, we can track all parts within the manufacturing process. Traceability and equipment that can handle the high hygiene requirements create the right conditions for safe food production”.

We hope you enjoyed this blog article about efficient and safe food production. Feel free to contact us with any questions or visit our website or social media channels for more information about FlexLink and our offer.

Leave a Reply