The coffee sector has evolved and acquired exclusive dynamics since the beginning of COVID-19. Its growth, also due to the success of capsules in various compatible formats, was driven by changing consumer behavior. With new market dynamics, new needs for coffee automation are emerging. Driven by the increased demand for coffee capsules and new flavors, the production chain has faced new challenges. Now more than ever, it is important to increase the production output and become more flexible and efficient.

Coffee Market & Impacts of COVID-19

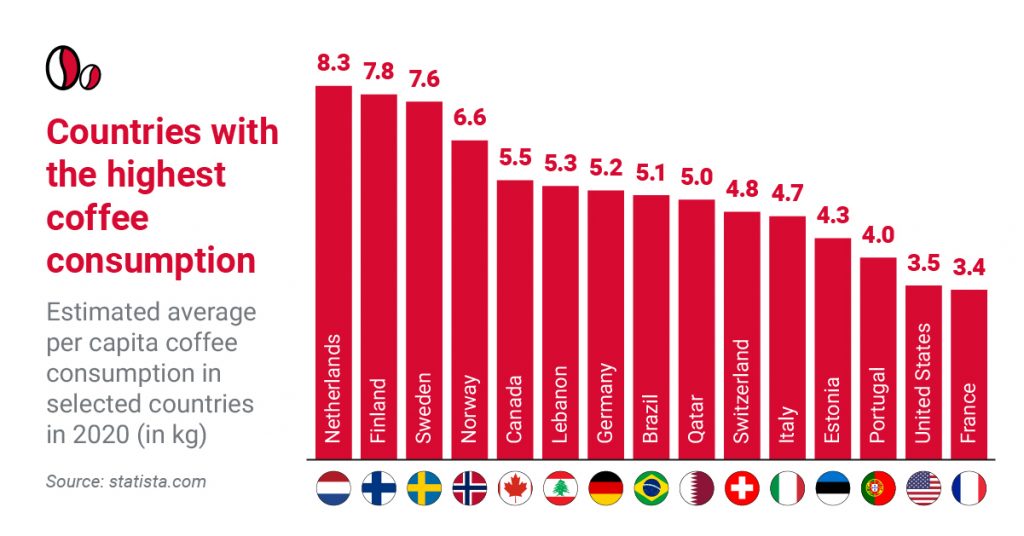

One kilogram of coffee a year: this is the per-capita consumption of coffee worldwide. The figure is significantly higher in a key market like the United States, where it amounts to 3.7 kg and even reaches 12 kg in Finland, the country with the highest per-capita consumption. (source: Statista). According to a report shared by Reportlinker in January 2021, the global coffee market is expected to grow from $140.2 billion in 2020 to $143.08 billion in 2021 at a compound annual growth rate (CAGR) of 2.1%. The growth is mainly due to roasteries rearranging their operations and recovering from the COVID-19 impact. It is no surprise, that the sale of coffee has shifted. Before the pandemic began, cafes and restaurants accounted for a large share of sales. However, due to the necessary closures, sales to the catering industry have declined extremely. At the same time, consumption has shifted and the market growth for coffee capsules, which people use at home, has increased significantly. The market is expected to reach $193.78 billion in 2025 at a CAGR of 8%. Large-scale distribution performed well, showing a revenue boost of +38% compared to 2019 in the US market alone. In particular, the sale of capsules and pods raised, witnessing a yearly increase of 7.72% worldwide in the forecast period of 2016-2026 (source: Tea and Coffee and Mordor Intelligence).

New Challenges

Due to the shift in coffee consumption, coffee producers are faced with a few challenges ranging from increased production efficiency to reacting to new consumer trends. As demand increases, so does the pressure on producers to respond to demand as quickly as possible. Production lines must be flexibly reconfigured, if possible, without any downtime. Furthermore, consumers are demanding an increasing variety of tastes and an increased sustainability awareness. Therefore, coffee producers are driven to invest in process and packaging by updating plants with low-impact solutions that increase efficiency while cutting down consumption. This translates into a great need for automation, especially in the phases downstream of packaging. So, what are the key challenges and market needs of the capsule market?

The right compromise between sustainability and functional capacity

The sector of consumer goods is characterized by increasing demand for a wide product offer. Coffee is no exception: today the main trend is a healthy lifestyle and sustainability. According to a report published by Boston Consulting Group and Trivium Packaging, in a key market like the US over 70% of consumers are willing to spend more for a product with “green” packaging. Producers react to the market needs by offering capsules made from sustainable materials. One example is compostable capsules. The material must guarantee long shelf life and should disintegrate quickly once it is discarded in the environment. Challenges that arise are higher production costs and a need for delicate handling. Since the capsule is even more sensitive due to the material, careful handling is particularly important in the process. Delicate handling solutions not only reduce costs for the producer. It is also an important sustainability aspect, as fewer resources are wasted in the production process.

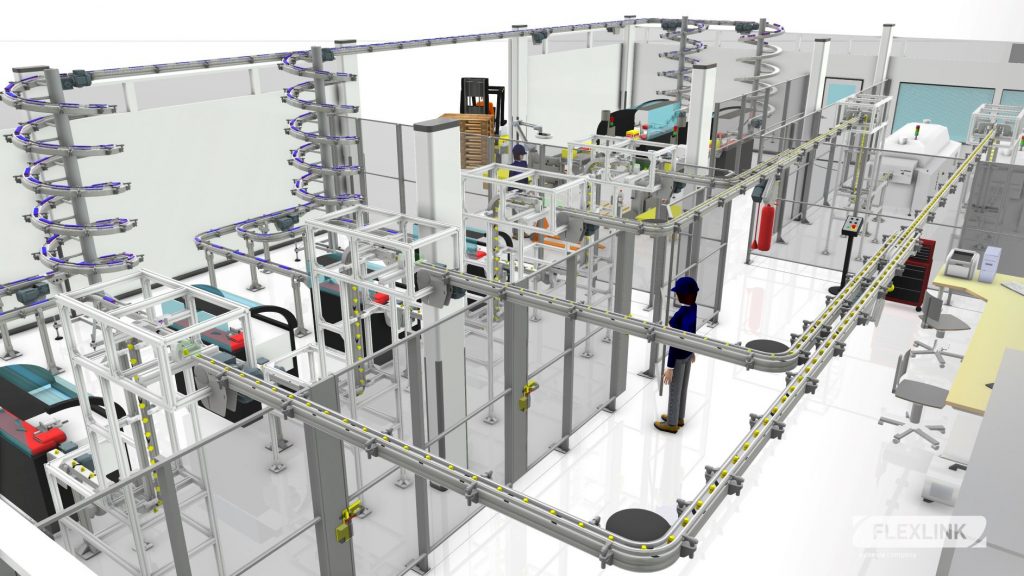

FlexLink has always approached the market with a complete vision of the supply chain, analyzing both the trends of the variety of sectors in which it operates, and the technical needs expressed by its clients. We offer handling solutions for all types of capsules and pods on the market and guarantee delicate, careful handling of biodegradable material as well. Besides traditional aluminum or stainless-steel conveyors, FlexLink presents solutions such as Wedge, a system for elevating production flow that is designed to optimize production and offers a wide range of settings and layouts. The modules can be customized further with automated cleaning systems. This is a very important feature in the coffee sector because during primary packaging, the production environment is often affected by the dispersion of coffee in powder form.

Flexible coffee automation solutions as a reaction to a demanding market

FlexLink offers handling solutions with state-of-the-art technological features that allow quick format change and ease of use. As far as packaging is concerned, it is worth noting that shape also impacts sustainability: smaller packages save not only packaging material but also space. As a result, smaller packages are easier to stockpile and transport in the downstream phases. For secondary packaging, FlexLink offers case packing solutions such as RC10, a collaborative robot that can operate with boxes of different sizes and weights and significantly facilitate the handling and stockpiling phases that follow primary packaging. Overall, FlexLink offers solutions that increase line efficiency, reduce costs and, consequently, cut down consumption.

Get in touch

Would you like to know more about production flow solutions to optimize your production?

Please get in contact at info@flexlink.com and visit us here for more information. We look forward to hearing from you!

Leave a Reply