Thanks to new and innovative solutions, the manufacturing industry is going through a remarkable development. A large interest in environmental-friendly solutions, as well as a growing need for increased production efficiency, have lead to trends such as individually adjusted production solutions, sustainable and energy efficient productions, digitalization and automation. In this article, I will walk you through the top 4 trends in the manufacturing industry and describe what they mean for your production.

Improve production capacity and simplify production processes

Individually adjusted production solutions, sustainable and energy efficient productions, digitalization and automation are top trends within the manufacturing industry in 2017. The trends focus on the environment as well as simplifying and streamlining production processes and improving production capacity.

1. Individually adjusted production solutions to fit your specific needs

The increasing need for customized products require both flexible, value adding processes and bespoke production flow solutions to match quality and capacity needs. The trend has been increasing in the manufacturing industry for years but it is not until now it can be done in an efficient way. New digital solutions enable production flow solutions to be adjusted to fit specific industries, processes, products and factory plants. In addition, the digital technology allows both software and IT solutions to be adapted to specific production needs in an easier way than before. Individualized products and traceability are strong triggers of this development.

2. Sustainable and energy efficient production flow solutions

A growing trend in the manufacturing industry is to use production flow solutions that are energy efficient and sustainable. Instead of using pneumatics we can see an increasing use of electrical motors, that run for example dividers, stoppers and grippers. When it comes to material, we see more customized material combinations with qualities that fit specific production processes. For example, we mix different materials to find combinations that have low friction and energy use, which are common needs in most industries. To find new material combinations many designers turn to nature for inspiration, where for example water repellant plants inspire the production of new materials with hydrophobic behavior. Plastic based on corn or ricin have increased in popularity when manufacturing products that are bio based.

A growing trend in the manufacturing industry is to use production flow solutions that are energy efficient and sustainable. Instead of using pneumatics we can see an increasing use of electrical motors, that run for example dividers, stoppers and grippers. When it comes to material, we see more customized material combinations with qualities that fit specific production processes. For example, we mix different materials to find combinations that have low friction and energy use, which are common needs in most industries. To find new material combinations many designers turn to nature for inspiration, where for example water repellant plants inspire the production of new materials with hydrophobic behavior. Plastic based on corn or ricin have increased in popularity when manufacturing products that are bio based.

3. Digitalization helps to avoid unforeseen costs and production stops

The digitalization develops the production flow solutions in many ways. It allows the manufacturing equipment to receive as well as send information to each other in order to adapt the production based on the equipment’s performance. In addition, the machines can inform in advance if they detect something that could cause a production fault in the future. That makes it easier to apply preventive maintenance, which helps to avoid unforeseen costs including production stops. When machines share information, it results in large amounts of data. To be able to define trends based on the data, the data should be stored in the same place. Therefore, the majority saves the information in the cloud. The trend of gathering and analyzing data in the cloud allows you to plan your production in a more efficient way, which often results in savings regarding both costs and time.

The digitalization develops the production flow solutions in many ways. It allows the manufacturing equipment to receive as well as send information to each other in order to adapt the production based on the equipment’s performance. In addition, the machines can inform in advance if they detect something that could cause a production fault in the future. That makes it easier to apply preventive maintenance, which helps to avoid unforeseen costs including production stops. When machines share information, it results in large amounts of data. To be able to define trends based on the data, the data should be stored in the same place. Therefore, the majority saves the information in the cloud. The trend of gathering and analyzing data in the cloud allows you to plan your production in a more efficient way, which often results in savings regarding both costs and time.

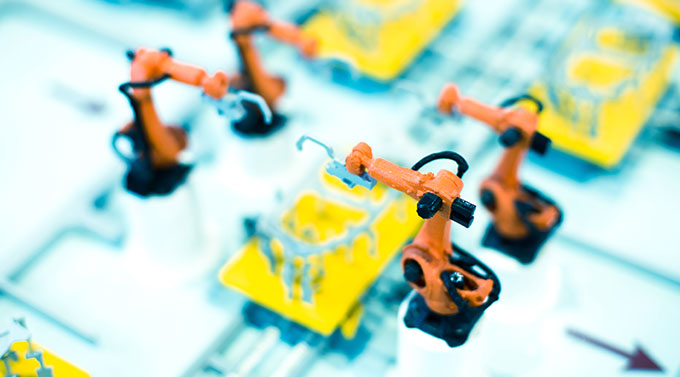

4. Automation through robotics improves production efficiency

The trend to automate production is clear and the use of robotics is increasing, which enhance the production efficiency to new levels. Collaborative robots are increasing in popularity since they can work alongside humans and be protected by sensors instead of cages or enclosures. Together, humans and collaborative robots get more done, which increases the production’s competitiveness.

The trend to automate production is clear and the use of robotics is increasing, which enhance the production efficiency to new levels. Collaborative robots are increasing in popularity since they can work alongside humans and be protected by sensors instead of cages or enclosures. Together, humans and collaborative robots get more done, which increases the production’s competitiveness.

Both automation and digitalization are especially evident in the automotive industry, which is going through a digital transformation. The cars are constantly developing, turning into smart machines talking to each other. That leads to new elements in the production chain, such as the installation of batteries and computers in the cars. Thus, the digital development of the products affects how the car factories will work with automation in the future.

Stay updated to keep track of new innovation and trends in the manufacturing industry

The background to these trends lies in several new innovations that have matured over a long period of time. The manufacturing of electronics in terms of censors and circuit boards has become more cost effective. Also, the software development has taken big leaps in how to make software more intelligent.

FlexLink will focus on these trends in 2017 and find new solutions on how to use effective production techniques, how to collect and save data and innovative ways to use robotics in production. To keep up with new innovation and trends, we cooperate with partners such as research institutes and universities that contribute with new and different perspectives. Individually adjusted production solutions, sustainable and energy efficient productions, digitalization and automation are exciting trends in the manufacturing industry in 2017 and we, at FlexLink, look forward to following and driving these trends forward, for the sake of our customers and the industry.

How do you think these trends will affect the manufacturing industry? Please share your thoughts with us in our social media channels, or by commenting the article below. Don’t forget to contact me with questions, or visit our website to read more about our industry expertise.

Thanks for your hard work. Nice information and very much appreciated.

Thanks! We’re happy to hear you find the blog useful.

Your article was very interesting and useful. i know a new details on this blog.this is helps to my article.thank you for upload this blog.